WhatsApp)

WhatsApp)

Sieve Analysis For the characterization of bulk goods of different forms and sizes the knowledge of their particle size distributions is essential The particle size distribution ie the number of particles of different sizes is responsible for important physical and chemical properties such as solubility flowability and surface reaction

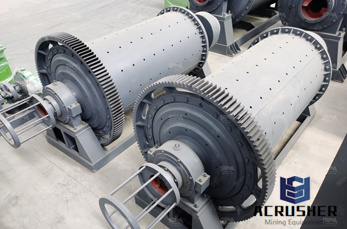

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size

Rotary Drum Screen Munson Machinery Grain Cleaning Testing Analysis Screeners A new compact Rotary Drum Screen from Munson Machinery removes solids from industrial and municipal waste streams and recovers solid product from process streams at rates from 600 to 2790 galmin 2270 to 10560 litermin without blinding or clogging the screen while reducing floor space and

Ball mill an overview sciencedirect topicshe ball mill is a tumbling mill that uses steel balls as the grinding medie length of the cylindrical shell is usually 11times the shell diameter figure 8e feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 2040 water by weight

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet or dry grinding the high amplitude VibroEnergy Grinding Mills range from 1 ft³ 36 liters to 75 ft³ 1934 liters of volume

An alternative approach to determine the effect of closing screen size on the Bond ball mill work index BW i in the absence of extensive test work is to use computer simulation The batch grinding process has been modelled using the size–mass balance approach Austin 37 Chapter 11 and if we can do this then we can effectively simulate the Bond ball mill work index test

Ball Mill The equipment to be used for size reduction is ball mill The ball mill is kind of grinder used for intermediate or fine grinding Ball mill is a metal cylinder which rotates about its horizontal axis The coarse material charged along with the metal balls breaks to fine powder by impact of metal balls 1

SAG mill product feeds two parallel ball mills of 66 m×111 m internal diameter×length each with a 97 MW twin pinion drive The ball mills are operated at a ball charge volume of

Cement mill is also called cement ball mill which is mainly used for grinding cement clinker in the cement production process It is one of the important cement equipment The output of cement mill is 21155 th and the specific surface area of cement is cm ² g

Vibration Feature Extraction and Analysis of Industrial Ball Mill Using In this paper the vibration signatures are analyzed for industrial wet ball mill using a MEMS spectral analysis to monitor the desired grinding status of the ore

The Work Index calculated from the testing can be used in the design and analysis of ball mill circuits The test requires a minimum of 10kg of sample that has been stagecrushed to 100 passing size of 335 mm Any screen size below 600µm can be used for the testwork depending on your requirements

ball mill circulating load from screen anlysis The Effect of Circulating Load and Test Sieve Size on The Bond In this study the effect of circulating load CL and test sieve size P which are inaccuracies of Bond grindability on the Bond ball mill grindability Ghg and work index W are investigated based screen SERVICE ONLINE GET PRICE

ballmill Home ballmill rational designed laboratory ore dressing vibrating screen design the company is committed to building the Chinese brand mine crushing and processing machinery mainly crusher mill sand making our products iron ore vibrating screens in more than one hundred of the worldsales of countries and regions

Particle size distribution influences the physical and chemical properties of solids Therefore this criterion is of highest importance in the context of science and quality control RETSCH sieve shakers test sieves and evaluation software provide the key to easy rapid reproducible and above all accurate analyses

The Mikro Pulverizer Hammer Screen Mill is a high speed mechanical impact mill designed for continuous size reduction of a wide range of materials down to D90 45 μm This device has evolved into the preeminent industrial mill with thousands of worldwide installations

Although ball mill has basically completed its localization the research and analysis on the ball mill has been staying on traditional level The traditional design of ball mill is based on the calculation of the thickness of grinding machine barrel To reinforce plate arrangement the method of

screen analysis mineral ball mill 187inclined vibrating screen vibration analysis Ball Mill for kaolin is the common grinding mill in kaolin production line it is used for coarse grinding the finished size is 0074 04 mm Raymond Mill is the traditonal Grinding mill and porpular around the world

The FC Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ores GRINDABILITY IS THE NUMBER OF NET GRAMS OF SCREEN UNDERSIZE PRODUCED PER REVOLUTION OF THE MILL

CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding for continuous or batch type operation in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings

Laboratory Ball Mills Ball Mills use grinding media in spherical or cylindrical shapes in rotating containers to grind a wide range of material types to very fine sizes Jars and grinding media are available in a wide variety of material types to optimize performance characteristics for longterm wearresistance low contamination levels or economical operation

mill liners may also affect grinding in cases of severe wear Fig 2 Screen Analysis of Ball Mill Cyclone Overflow 33 Settling Rate Test Fig 3 A to D presents the effect of settling velocity on particle siltation in various systems In all cases settling velocity was high compared with

WhatsApp)

WhatsApp)