WhatsApp)

WhatsApp)

DIAMANT Vertical Grinding Mill The Diamant vertical grinding mill is a result of more than 100 years of production experience and continuous product improvement Today the mill is a modern high quality product with outstanding performance The vertical mill is now CE approved Open Catalogue

JET Vertical Milling Machines are manufactured for precision reliability and durability Table sizes ranging from 8" x 36" to 12" x 54" and drivetrains of step pulley variable speed and electronic variable speed allow for easy mill selection

Pre Grind Roller Mill Finish Cement The vertical cement mill grind materials to related fineness by grinding rollers you can easy Vertical Roller MillVertical Mill for Cement It is consist of separator grinding roller Separator controls the finished product output size greater than the specified size are

Vertical Grinding Mill is suitable for processing various nonflammable and nonexplosive mineral materials with Mohs hardness less than and humidity less than 6 it is widely used in the fields of metal

Vertical mills Flexible mills with integrated separator The vertical mill enables high energy economy and convinces with low specific wear values Drying of the feed material grinding separating and material transport take place inside the mill It is thus especially well suited for grinding products with high proportions of wet components

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills Our ATOX coal mill has large rollers with great grinding capability of all types of coal tolerating moisture levels up to 20 percent For the mining industry our semiautogenous SAG grinding mill uses a minimal ball

slag mill CENTER CHUTE By adopting Center Chute which enable Material feed vertically to table center from top of separator material on table are distributed ideally and ground with high grinding efficiency

The average vertical mill comprises a large vertical grinding chamber with a centrally located agitator which has a number of grinding disks mounted on it On the bottom of the shaft is a massive balance pulley which serves to help center the shaft and to a certain extent direct the flow of the product from the inlet which is at the bottom of the vessel

Supply Vertical Roller Pre Grinding Mill For Sale In AustraliaJapanGerman can product the crusher and grinding mill vertical roller mill pre grinder Read More Vertical Roller Mills for Clinker Grinding within Holcim with pre‐grinding Horomills 57 32 10 1 roller press pregrinder Vertical roller mill

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localised rises in cement

The Vertical Roller Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co Ltd Japan These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Rawmeal Grinding We have over two decades of experience in supply and installations of Vertical Pre Grinding

Vertical roller mills are developed to work as airswept grinding mills Roller mills are operated with throughput capacities of more than 300 th of cement raw mix Loesche mill Polysius double roller mill Pfeiffer MPS mill Loesche roller mill and Polysius roller mills are widely applied in cement raw material grinding

Pregrinding system with CKP vertical type mill is applied for increasing capacity and reducing power consumption of existing ball mill grinding system The capacity can be increased up to double 100 Also CKP mill achieves energy saving of 30 at most compared with conventional ball mill system

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills Our ATOX coal mill has large rollers with great grinding capability of all types of coal tolerating moisture levels up to 20 percent For the mining industry our semiautogenous SAG grinding mill uses a minimal ball charge

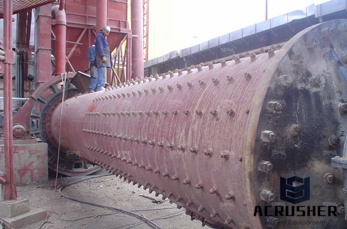

The mill is equipped with a discharge diaphragm at the end This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material Closed Circuit Ball Mill System Clinker Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement

It is a misunderstanding that grinding aids for vertical roller mills VRMs should stabilise the material bed between the rollers and the table by adhesive forces between the particles Grinding aids reduce the polarity of the cleaved surface and the attraction forces between particles

VerticalGrindingMill is the integrationof drying grinding classifyingand conveying which is widely applied to coal cement slag lime powder for power plant desulfurization nonmetallic minerals and other fields of milling It has strong adaptability to high humidity dry materials hard or easy to grind

Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings The materials such as clinker and gypsum fed into the mill are ground by compression and shearing forces between the grinding table and two or four rollers which are

Vertical Grinding Mill is the integration of drying grinding classifying and conveying which is widely applied to coal cement slag lime powder for power plant desulfurization non

vertical rolling pre grinding mill Cement mill Wikipedia A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement

HLM series vertical grinding mill is a kind of advanced pulverizing equipment integrated with drying pulverizing powder selecting and conveying It is applied as a good solution to the technical issue such as low output high energy consumption and high maintenance cost in the ordinary industry

A vertical milling machines spindle axis is aligned in a vertical manner to the machines bed That means that the cutting tool is arranged vertically to shape the metal or other material into the desired form

Vertimill is an energy efficient grinding machine They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns has recently developed a 4500 HP 3352kW Vertimill designated the VTM4500C

WhatsApp)

WhatsApp)