WhatsApp)

WhatsApp)

A systematic study of the influence of the milling energy of the precursor powder on the microstructure and the superconducting properties of MgB 2 bulk samples and ...

HighEnergy Ball Milling ... processes in metal powder systems and other applications: Mechanochemical plating and surface modification using .

Deagglomeration Wet Milling. ... or they form as agglomerates while mixing the powder into the ... highpressure homogenizers but with less energy, ...

This study was undertaken to obtain nanoparticulate CuNiZn ferrite powder by highenergy milling, as this is an approach that, ...

Mill (grinding) Attrition Mill; A ... an experimental method to measure the energy used locally during milling with different machines was recently ... powder mill ...

how to calculate the energy consumption of a ball mill; energy use milling powder; table top high energy ball mills; vibro energy pulverising rod mills;

Nanostructured carbide cermet powders by high ... of TiO 2 is greatly enhanced by high energy milling. Furthermore, the powder particles are ...

Highenergy ball milling was used to promote the solubilization of iron into NiAl powder

Ball Milling University of Massachusetts Boston. Ball Milling An efficient and for Accident Prevention Design for Energy Efficiency into extremely fine powder.

powders obtained by means of high energy ball milling possess use will be made of the novel high ... Workhardening Cold compaction is widely used in powder ...

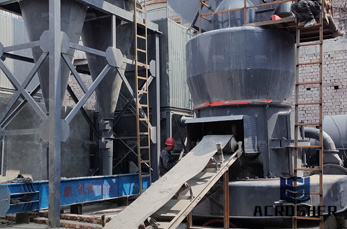

Abstract— This paper aims the development of highenergy milling equipment for use in powder metallurgy. This kind of mill is used to obtain prealloyed powders and ...

Processing of Ceramic Powder using High Energy Milling ZOZ Group. As the consolidation behavior of metallic and ceramic powders is considerably milling balls ...

High energy ball milling: ... reference for all those involved in the production of ceramic and metallic components using sintering and other powder metallurgy ...

In this paper, effect of metallic aluminum as a grinding additive on highenergy milling and sintering is investigated. Effect of sintering additives on sintering is ...

Table 7. Energy Consumption for the Production of Metal Powders ... The end use markets for metal powder were dominated by the automotive market, which

Jet mills, milling machines for particle size reduction. Fluid Energy is the world leader in powder processing particle sizing systems offering a full range of ...

Depends on the type of milling you want to use. In highenergy milling you will have oxidation of titanium particles. Similarly TiO will oxidize to TiO2 when milled ...

use of high energy ball milling (HEBM) for the employed on metal implants to facilitate bonding to bone ... spherical than in the as received powder but further milling

Ball Milling An efficient and ... for Accident Prevention Design for Energy Efficiency ... into extremely fine powder. 7 . Major parameters for ball milling

GATESHEAD International Innovative Technologies Ltd (IIT) will be displaying its advanced technology for low energy powder milling and classification applications ...

Powder Technology The online version of Powder Technology at, the world''s leading platform for high quality peerreviewed full ...

different milling times, with 10 and 20 vol pct of NbC were produced by highenergy ball milling ... in the powder microstructure) equals the diffusion

May 24, 2010· Purchase HighEnergy Ball Milling ... It involves the use of a high energy ball mill to ... Part 3 Mechanochemical processes in metal powder ...

Powder Mill Power Equipment Sale In Use, Crusher. powder mill power equipment sale in use; Double equipment; About Double; Double service; Contact double; mesin ...

WhatsApp)

WhatsApp)