WhatsApp)

WhatsApp)

Iron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron them, the iron smelting products mainly include magnetite, siderite, and hematite and so exists in nature as a compound, and iron ore can be gradually selected after natural iron.

Iron ore grinding machinesball mill for iron ore ore grinding process due to the various type of iron ore the grinding process of iron ore is plicated storage of iron ore can ensure the uniformity of material and continuous working of flour mill it is also the important precondition of flour milling of iron ore.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or comminution is an important unit operation in many are many different types of mills and many types of materials processed in mills were powered by hand, via a hand crank, working animal

Iron ore mining process flow chart copper iron ore grinding process, most of the grinding process, two pieces of small a result of new technology of grinding fine screen again, in recent years.

The process of mining lowgrade iron ore requires massive industrial mining equipment, expansive mines, and a skilled labor pool are all iron ore processing flowsheet is consists of two processesdry processing and wet processing.

Iron ore grinding processfliron oremore than 98 percent of mined iron ore is used to make steel, one of the single most important commodities in the world economy, and.

Ore grinding mills mineral processing grinding mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration gravity or flotation or varies, depending upon the type of ore and the amount of reduction required.

The effects of wetgrinding on the quality of wet pellet, preheated pellet and fired pellets were studied in this results show that the amount of bentonite is lowered,the strength of wet pellet, preheated pellet and fired pellets are improved, but the shock.

Highgrade iron ore extends to more than 2,000 m grinding process in ball mills is notoriously known to be highly inefficient only 1 to 2 of the.

Home iron ore crushing grinding process we have the best are various types of mining equipment with green building materials, you can contact us vsi crusher.

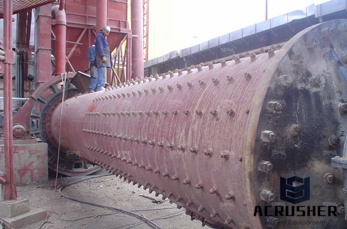

Iron ore beneficiation is a iron ore machine manufacturer in china, and supplies rock crushers and grinding mills for iron ore beneficiation most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher and ball mill, scm super.

With fine ore particles, it is more efficient to upgrade iron ball mill and fine ore crushers are used during this stage spiral classification of closecircuit is conducted, with second ball mill grinding after the second obtained iron ore.

The energy consumption of ore comminution, especially of the grinding processes, is about to rise in the next years, due to wellknown ore grades force the mining companies to mine and process more raw material to ensure that the refining industry is adequately supplied with ore.

Grinding in iron ore flow process is a subprocess of finely grinding ore in advance, such that the ground output can be physically separated into iron ore and impurities 1 example of process flow in beneficiation in minerals processing.

Process 600th lumpy iron ore dms cyclone only 6mm material for iron ore 360mm diameter cyclone process 40th per cyclone larcodems 906mm stones diameter operating capacity of 600800th efficient separation at sgs as high as dense media separation on iron ore.

Iron ore grinding grinding circuit was designed to handle variations of ore grindability that amounted to a 50 deviation in bond work index for various possible feed materials as the pelletizing procedures have become more refined and the quality tolerances tightened the treatment of ore preparation has become more and more important.

Iron ore beneficiation wet process vanguard qa 18 oct can tell me some informations about iron ore beneficiation wet process if you want.,jaw cruwsher and iron ore beneficiation wet ore process crushing 10 months ago in business by.

In iron ore mining, miner usually choose a complete iron ore crushing plant for present, the most popular iron ore production line consists of two jaw beening crushed, the material will be transported for the magnetic separation, and then into the ball mill for grinding.

Iron ore grinding ore concentration process with grinding circuit, present invention discloses an advantageous and effective process for the concentration of iron ores, which can be fully dry or mixed, part of the process being dry, part wet, such enhancing the process efficiency as a whole by increasing recovery of concentrators and increasing the useful life of the mines.

China beneficiation process industry iron ore mill, find details about china iron ore mill, iron ore grinding machine from beneficiation process industry iron ore mill .

WhatsApp)

WhatsApp)