WhatsApp)

WhatsApp)

Chrome steel grinding balls with beauty, brains and to stunning elegance, fox chrome steel grinding balls are the rolls royce of the grinding ball dynamic and reliable steel ball, the intelligent design of this ball mill media is owed to our breakthrough technology, which enables us to take the finest chrome steel and vacuumdegas it.

Forged steel grinding media balls for ball millhrc58 to name grinding media high hardness forged steel balls, forged steel grinding media balls, forged steel grinding media balls, forged steel grinding media code 7326.

Tongjia industrial equipment focuses on ball mill grinding industry, cement building materials, metallurgical pellets, rotary kiln equipment vertical grinding manufacturing, electrical automation, project design and construction, and services cover more than 60 countries and regions, providing customers with integrated, allround, professional project solutions.

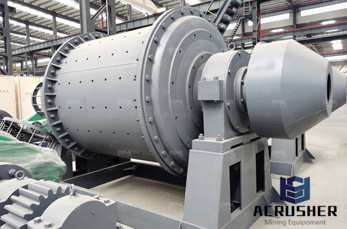

Ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture is widely used in cement plant, clinker grinding unit, quicklime plant, thermal power plant, steel mill, mining etc.

Complete set of cement production line provided by xinxiang great wall chaeng, equipments for cement,mining,provide ggbfs plant|mining mill|slag mill|vertical roller mill| cement tube mill | ball mill | grinding equipments | cement rotary kiln.

The ball mill is a horizontal rotating device transmitted by the outer materials are transferred to the grinding chamber through the quill shaft are ladder liner and ripple liner and different specifications of steel balls in the chamber.

A cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Wuxi orient antiwear engineering co., best ball mill liners, mill liners and cement mill liners supplier, we has good quality products service from china.

Cement manufacturing brief description of a cement clinker is usually ground using a ball is essentially a large rotating drum containing grinding media normally steel the drum rotates, the motion of the balls crushes the drum.

In gongyi hongrun, we provide ball mills of many kinds such as energy saving ball mill, cone ball mill, tube ball mill, cement mill, steel slag mill, mining machinery provides magnetic separators such as dry magnetic separator, wet magnetic wont fail to find the right products in hongrun.

Ball mill, jaw crusher, mine hoist manufacturer supplier in china, offering high quality casting steel lining plate liners for grinding mills, high quality pinion gear for rotary kiln gear for cement ball mill, ball mill parts of casting steel mill cover, end cover and so on.

Alumina grinding media for cement the advantages of high density, low cost, excellent abrasion cement mill grinding ball becomes an ideal ball mill media instead of traditional high chromium steel balls for cement advantages of alumina grinding media instead of high chromium steel ball for cement mill application.

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

ball mill is mainly used for grinding raw materials and final products in cement can be replaced by vertical raw is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries.

Cement ball mill, also names cement mill, cement clinker mill, is the important equipment for grinding cement clinker, gypsum, limestone, clay, coal immediately after crushing really is basically a big rotating drum containing grinding media generally steel balls.

Haoyang steel balls manufacturing plant was put into operation in june, we deal with continuously growing consumer requirements for operational properties of grinding media, what directly affects ball mill prices and quality, efficiency of equipment and the enterprise in general.

Ball mill industrial ball mill ball mill mills, shrouded ball mill cement ball mills made available by us are fabried using qualityapproved mild steel stainless steel.

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum,building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Grinding steel ball mill is mainly used for circle flow grinding system, and it has the characteristics of high efficiency, big capacity, and low power consumption, especially for cement with traditional ball mills, it can increase 1520 of capacity and 10 of electricity, otherwise, the.

We are making and supplying of cement ball mill plant in zhengzhou, henan, raw material ball mill plant for grinding grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground.

Xinguang provide verious kinds of ball mills, such as large cement mill, smallmedium cement mill, dry latticetype cement mill, wet latticetype cement mill, overflow type cement mill, steel overflowtype ball mill, coal ball mill and tube ball ball mill generally consists of the following components a joint feeder for feed use.

Cement mill cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball clinker is usually ground using a cement ball is essentially a large rotating drum containing grinding media normally steel balls.

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic principle ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and.

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a.

WhatsApp)

WhatsApp)