WhatsApp)

WhatsApp)

Mining Industry: What is the difference of ball mill, attrition mill, sand . Most mills used in mining rely on impact to breakdown rock to a suitable size for downstream . The impact can be rock on rock such as in an Autogenous ...

Improved Flotation Recovery – Xstrata | IsaMill Grinding in a steel mill can achieve liberation, but often at the cost of poor flotation chemistry. . ... FLOTATION PLANT DESIGN AND PRODUCTION PLANNING . – SGS flotation ...

First Industrial Flotation Column in a Paperboard Recycling Plant 1 Yuxia Ben, 1 Gilles Dorris, 1 Natalie Pagé, 1 Sylvain Gendron, 1 Norayr Gurnagul, 2 Christian Desrosiers, and 2 Patrick Maltais 1Pulp and Paper Research ...

Fine Grinding as Enabling Technology – The IsaMill Pease, (1), Young, (2), Curry, (1) (1) Xstrata Technology (2) Xstrata Mount Isa Mines Introduction The new generation of stirred mills like the IsaMill has ...

People have their favourites and are reluctant to shift allegiances even for new projects." Flotation cell design FL Minerals'' Asa Weber and Dariusz Lelinski explain that the company uses a continuous process improvement ...

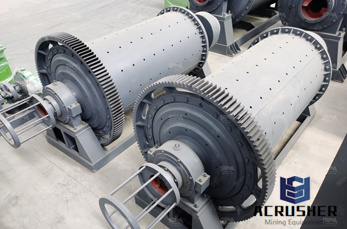

LM Vertical Grinding Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment. READ MORE B series vertical shaft impact crusher High precision 1 ...

Poor Fines Recovery in Flotation IsaMill grind a gold ore in a ball mill with 9 mm balls with an IsaMill with 2 mm media. The ... Managing the impact of grinding on flotation performance is the third crucial .... The IsaMill grinding media ...

mill control system to facilitate the mill reacting to the impactmeter information, the instrument does not actually control the mill and this remains the function of the mill control system. The instrument provides the operator with 6 ...

Mill No. 3 was designed in the same design as Mill No. 2. Read More The Magotteaux Mill®: investigating the effect of grinding media on Many laboratory studies are completed each year exploring the flotation response of old and ...

impact on mill design and flotation control of new discoveries. ... Flash Flotation and Regrind Mill Fosterville Gold Mine Minerva . Flash Flotation and Regrind Mill. Read more gold beneficiation flotation circuit SBM Mobile ...

Companies must consider the impact these fees will have on how much capital they can raise from a new issue. . Flotation Cost = the ratio of flotation cost to the price . Flotation is the process of changing a private company into ...

PROCESS DEVELOPMENT AND PLANT DESIGN Better processing Aveva impact on overall plant performance and the ... Additional flotation capacity will be installed as ... PROCESS DEVELOPMENT AND PLANT DESIGN On ...

how does a flotation mill work Protable Plant ? how cyclone work in cement mill ? how does a flotation mill work? how does a ball mill crusher work ? how ... Chat Online Get Price.

impact on mill design and flotation control of new sized grinding mills and steady feed to the flotation circuit. ... SAG hardness, in the range of to 34 kWh/t to grind to mm, and the calculation of the. Grinding Media — Its ...

impact on mill design and flotation control of new impact on mill design and flotation control of new Froth flotation grinding mills,Copper ore ball mill Beneficiation Plant /5 Costerfield Operation, Victoria, Australia NI 43 ...

and ball mill at the design stage was the second new discovery. The impact of these new discoveries on mill design and flotation control is the subject of »More detailed Autogenous mills, semiautogenous mills and ball mills for » ...

2017/08/11· On Aug 25, 2013 Valery Morozov published: Modern Systems of Automatic Control of Processes of Grinding and Flotation of CopperMolybdenum Ore Request fulltext Modern Systems of Automatic Control of Processes of · with ...

impact on mill design and flotation control of new discoveries discovered for mill design measurements using the patented SAGDesignTM test. Crushing, Rod ... sized grinding mills and steady feed to the flotation circuit. Read more ...

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral ...

New directions in flotation machine design . New directions in flotation machine design on ResearchGate, the professional network for scientists. » Learn More how does a mineral flotation machine work how does a mineral flotation ...

The impact of ore characterization and blending on . SAIMM consisting of a new 1 750 m vertical shaft and development of the . sequential flotation process that extracts copper concentrate, lead concentrate and zinc. Live Chat

Page 1 of 7 PAPER # 1882 SYMPOSIUM: MINERAL PROCESSING – Mineral Processing of Complex Sulphides IMPACT ON MILL DESIGN AND FLOTATION CONTROL OF NEW DISCOVERIES IN THE RELATIONSHIP ...

Advanced process control for grinding circuits Unlock the unknown potential of your mill White paper, June 2015 Recent copper price evolution pushes modern mining industry even harder to achieve highest production with maximum ...

Large differences between macro and micro grindability relationships have been discovered for mill design measurements using the patented SAGDesign(TM) test. Crushing, Rod and Ball Mill Wi tests, and breakage parameter ...

WhatsApp)

WhatsApp)