WhatsApp)

WhatsApp)

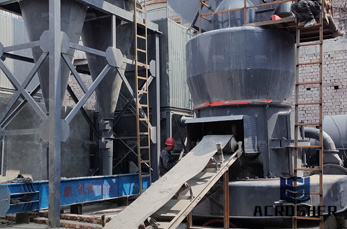

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on the size, ... density, ball size distribution);

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge angles 205 .

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

W is the work index measured in a laboratory ball mill (kilowatthours per metric or short ton) P 80 is the mill circuit product size in micrometers;

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive ...

MILLING CONTROL OPTIMISATION ... Millstar Mill Discharge Density Estimator Millstar Ball Load Estimator Millstar Mill Power Filter

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the ballto ... mill volume. Now, assume the bulk density of ...

how much slurry ball mill porcellin ball size. how much slurry ball mill porcellin ball dispersed slurry, I''m opting ballmilling. and the high density balls are ...

Powder Technology, 59 (1989) 285 293 Slurry Density Effects on Ball Milling in a Laboratory Ball Mill C. TANGSATHITKULCHAI Department of Chemical Engineering ...

Chrome Steel Balls – Grinding Media for ... the high density and superb hardness of FOX Chrome Grinding Balls make these grinding media balls ideal for ball mill ...

The effect of pulp density to ball mill grinding The role of the ball mill grinding depends mainly on the grinding media circle movement grinding shattered role.

Creative grinding solutions Sika Group. Figure 1: total feed of cement mill consisting of fresh material, the return from . production rates of ball mills and ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ... Density: The media should be ...

operating parameters other than ball level, such as pulp density and liner configuration. ... A direct measurement of the ball level in the mill, more

High density alumina ... Distributor* Distributor of balls as grinding polishing medias for use in ball mills. Ball mill balls can be customized as per ...

China High Density Zirconia Oxide Ball Mill Grinding Media Good Price, Find Complete Details about China High Density Zirconia Oxide Ball Mill Grinding Media Good ...

Impact Resistance Alumina Ceramic Grinding Lining Bricks For Ball Mill (2) High density and small thickness can increase the effective ground space and increase the ...

About densitys in a ball millrelated information:peer reviewed article bioresources. com halvarsson et al. (2010). » Learn More. Typical Physical Properties of ...

Planetary Ball Mill; Laboratory Jet Mill; ... While steel grinding media is attractive because of its relative density and low cost it can produce graying of ...

High density alumina ... Distributor* Distributor of balls as grinding polishing medias for use in ball mills. Ball mill balls can be customized as per ...

Our depot contains over 15,000 free essays. Read our examples to help you be a better writer and earn better grades!

Optimisation of the secondary ball mill using an online ball and pulp load ... It can be seen that when the inmill density increases the ball foot angle decreases.

WhatsApp)

WhatsApp)