WhatsApp)

WhatsApp)

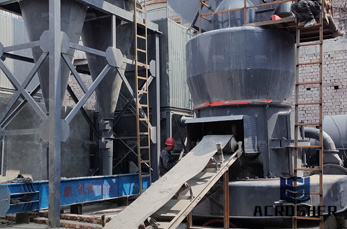

Cement vertical mill also called roller mill is another raw mill commonly used in cement plants Compared with the cement ball mill it has a great difference in structure grinding principle process layout automatic control and energy consumption which play an important role in the modern cement

Raw Mill In Cement Plant This is achieved in a cement raw mill The grinding process is controlled to obtain role of ball mill in cement process Grinder Mill play an important role in the cement industry Grinder Mill play an important role in the cement industry

INTERNAL AUDIT – IN CEMENT INDUSTRY Internal audit function has vast scope in Cement industry being in manufacturing sector and plays key role in keeping the wheels always on The very reason for saying this on continuous basis is the constant review of built in ''internal controls'' in the Organization needs a patrol just like

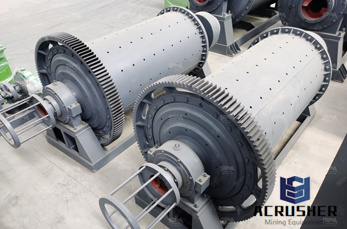

Raw Mill In Cement Plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Its mainly used in grinding raw materials and end products in cement plant

Aug 30 2012· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale fly ash mill scale and bauxite These raw materials are directly brought from other sources because of small requirements

The raw mill considered in this study is located in a cement plant located in Sanliurfa Turkey The plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tonsh

The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker The gypsum controls the

Sep 04 2013· re Cement Process Quality Control 1 Mineralogy of Raw Material used for manufacturing of Cement You need a good deal of reasonably pure limestone or marble of chalk or othe form of CaCO3 some shale clay schist or other material that is mainly composed of compounds of silicon iron and aluminium

Use of raw materials in the cement industry Procurement of local raw materials forms the basis for the manufacture of cement and represents an essential component of industrial value creation chains in Germany The most important base materials in cement include limestone clay or the naturally occurring mixture of the two lime marl

In the wet process water is added to the raw mill during the grinding of the raw Cement Plant Kawasaki Heavy Industries In addition to total engineering we manufacture raw mills kilns and cement mills which are integral to the quality and energy saving in cement manufacturing Cement Kilns Raw Material Preparation

Playing a key role in the moving mixing heating and cooling processes Howden products are used throughout the cement production process Our blowers are used to move the iron ore calcium carbonate silica and alumina immediately after extraction and continue to be used throughout the process and once the end product is generated and needs transported

Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding Raw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and other materials metallurgy mine chemical and construction

The study indicates that for a dry type cement production process the carbon dioxide emission intensity for kiln feed preparation process is about 54 kg CO 2 per ton cement produced In this study the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is investigated

Role Of Raw Mill In Cement Plant Minevik Role of raw mill in cement plant the cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing mainly limestone and clays a limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km read mode

From both a process and chemical viewpoint it is beneficial to minimise clinker temperature as it enters the cement mill The milling process generates heat and excessive mill temperatures are undesirable It is clearly helpful therefore if the clinker is cool as it enters the mill

Duties of raw mill attendant in cement plant crusher duties of raw mill attendant in cement plant cement mills fluxo coal they work on repairs and the nature of their duties is such that it soils their clothes more how does a cement plant work crushergoogle

And this quality is achieved during cement production with exactly matched process steps In the first stage the raw meal is produced as described below Schenck Process measuring and feeding devices play a major role in this process

Raw mill is generally called cement raw mill raw mill in cement plant it refers to a common type of cement equipment in the cement the cement manufacturing process raw mill in cement plant grind cement raw materials into the raw mix and the raw mix is sent to the cement kiln to make cement clinker next clinker and other admixtures will be ground into finished cement by cement mill

Energy and Exergy analysis of the Raw Mill in the Cement Plant 57 The calcined material then enters to the burning zone of the kiln and the entire chemical reactions takes place there and clinker is formed The clinker then passes through a clinker cooler for cooling The primary air from the primary air fan and secondary air drawn

Cement Raw Materials The coordinates of the grinding table diameter and number of rollers can be read off from the table The xcoordinate indicates which product throughputs can be generated using the respective mills

function of raw mill in cement plant A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of cement Rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement mill The raw milling stage of the process effectively defines the chemistry of the finished cement and has a large effect upon the

The preparation of cement raw materials is a link of cement production The cement raw materials is formed with calcareous materials clayey materials and slight corrective material in appropriate proportion and grinded into certain fineness The raw material production of cement plant can be classified into four steps crushing grinding mixing and homogenizing

Project Description Conversion of existing long dry kiln to a preheaterprecalciner kiln and increasing the plant capacity from 1500 Mtpd to 2400 Mtpd clinker which was part of a larger modernization investment at the Lafarlcim Hagerstown plant The project consisted of the following new raw mill feed bins raw mill system preheater main baghouse alkali bypass baghouse process fans cooler

WhatsApp)

WhatsApp)