WhatsApp)

WhatsApp)

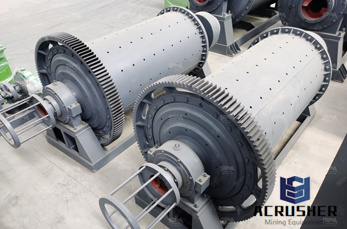

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum

Based on the density of the rock body being blasted the drilling pattern and a whole host of other factors there will be a range of rock sizes included in the run of mine ROM ore Smaller pieces will fall through the rock crusher and make their way directly to the SAG mill or ball mill

In cement production line rotary kiln ball mill is the indispensable equipment rotary kiln and ball mill production by Henan Zhengzhou Mining Machinery Co Ltd can improve the efficiency of the cement production saving energyhelp you get more economic interests

Vertical Roller Mill VRM is the most advanced technology in cement production procedure Bashundhara Cement has adopted VRM from LOESCHE Germany in both the factories to ensure the best quality With higher fineness achieved with VRM it creates stronger and better quality concrete and thus proves its superiority over other cement brand

ALPA''s ball mill classifying production line with reasonable production capacity large output stable operation and stable product quality Influencing factors of

Ball mill is the material to be broken and then smash the key equipment widely used in cement silicate products new building materials refractory materials fertilizer ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores

Advanced Technology Best Cement Ball Mill For Mini Cement Plant by seaworthy packaing spare parts packed in wooden case Port Qingdao or Tianjin port Lead Time

ALPA''s ball mill classifying production line ball mill and classifier work well together can complement each other high efficiency large output stable operation and stable product quality

Small ball mill is widely used for the cement the silicate productnew type building material fireproof material chemical fertilizer black and nonferrous metalglass ceramics and etc Our small ball mill can grind ore or other materials that can be grinded either by wet process or by dry process

Their production represents 90 percent of the sizereduction methods used to produce powder materials today air classifying pin hammer jet and ball mills As products and technologies become more advanced in today''s markets the need for materials with specific properties for special applications becomes more important

The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by impact and attrition The degree of milling in a ball mill is influenced by Residence time of the material in the mill chamber The size density and number of the balls

Jaw crusher jc 60 100 and jc 100 200aw crusher jc 60 100 dan 100 200 jc jaw crusher ballmillchina the jaw crusher is also called the jaw breaker it has been widely used in many fields such as it has a worldwide advanced crushing technology and producing standard and the jc series jaw crusher can crush the material with high

If you need to buy laboratory ball mill there may be lots of brands and manufacturers like Retsch Fristch or other for your option Tencan shall help you to save a great deal of cost because Tencan always offers customers similar machines and equipment at 15 or even

process of gypsum production new technology ball mill Mineral Processing Technology Testing Process Design Gypsum grinding mill for gypsum powder

Mar 18 2018· Cylindrical energy saving grid ball mill is one of energy saving mills developed by our company which is easy to start and saves 2030 energy It is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the

The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of

JoyalGrinding MillFine Grinding MillMicro Powder MillUltrafine MillRaymond Mill From China page is about the grinding millincludes micro powder millhigh pressure millygm modelraymond mill3r4r5r6r and ball millsif you want to buy these joyal grinding mills

The production rate of a ball mill process is indicated in the manufacturers technical specifications and it is proportional to the drum rotation speed The energy needed for the production of 1 ton of lead oxide is fairly constant when the mill operates at between 55 and 90 of its critical rotation speed

new products vietnam silica sand ball mill Xinhai provides optimized solutions for your mine onestop serv for mineral processing plant include sample test mine design equipment manufacture etc The optimal benefit of modern mining enterprise profits from advanced technology which is embodied in rational process flow and highefficiency and energysaving equipment

Solutions range from crushers shredders and granulators to hammer ball and pin mills air classifier or jet mills colloid and corundum mills just to name a few This may be because the complexity of food milling applications varies significantly You will need different equipment depending on

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds spreads creams for fillings and coatings cocoa masses nut pastes and other fatbased masses The unique grinding chamber delivers onestepgrinding at low temperatures ensuring that your product has the highest and consistent quality

WhatsApp)

WhatsApp)