WhatsApp)

WhatsApp)

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material.

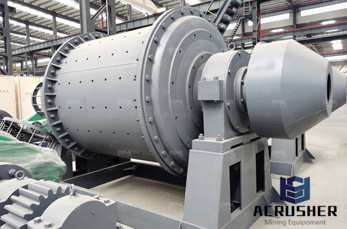

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

We are manufacturer, exporter and supplier of high speed disperser, high speed mixers, industrial mixers, mixing equipment, industrial mixing equipment, high speed ...

Speed Feed Calculators and Common Formulas Speed Feed Calculators. Dapra''s Speed and Feed calculators will automatically provide the necessary speed and .

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

84 0J HQWHU RI JUDYLW RI WKH FKDUJH G)UDFWLRQ F F Figure Simplified calculation of the torque required to turn a mill. RI FULWLFDO VSHHG 3RZHU

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

High Shear Mixers. Ross is the leading manufacturer of high shear rotorstator mixer homogenizers and highspeed dispersion equipment for the adhesives, chemical ...

Tabtight professional, free when you need it, VPN service.

DYNO®MILL offers unmatched versatility in the comminution of suspended solids. models are available from liters to 600 liters

116 Note: All speed and feed data are suggested starting points. They may be increased or decreased depending on machine condition, depth of cut, finish required ...

Datron''s M8 Cube uses a high speed spindle and HSM techniques to achieve maximum productivity... What is High Speed Machining? There are many definitions for High ...

Precision. Highspeed applications for ultraprecision equipment require tight tolerances and superfine surface finishes. Timken precision ball bearings, which ...

AIRCRAFT SPRUCE CATALOG PDF DOWNLOAD : To view the files you''ll need the Adobe Acrobat reader. If you don''t have the Adobe reader, you can download it ...

Open the lid to your Ball Mill and add the following: 150 grams of Potassium Nitrate, 30 grams of Charcoal Powder, and 20 grams of Sulfur ( if your lead balls are not ...

Product Description CNC Supra Mill 9 x 49: 9, Easy to learn and operate. It''s your classic vertical knee milling machine with CNC technology.

Heavy Industry produce Crushers, Jaw Crusher, Impact Crusher,Raymond Mill, Sand Making Machine etc. Each series include maximum, medium and minimum types.

The diagram above shows the difference in clearing path shape between a fish tail, ball nose and V tools. Ball nose mills are often selected when doing 3D contouring ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

To download speed and feed charts in Adobe PDF format, click on the links below: High Performance End Mills:

Introduction. A high speed spindle that will be used in a metal cutting machine tool must be designed to provide the required performance features.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low Speed Ball and tube mills. A ball mill is ...

WhatsApp)

WhatsApp)