WhatsApp)

WhatsApp)

Roller mill ing principle mill wikipedia, the free ing, motor drives the hanger of the grinding roller to rotate through v pulley and centre of roller mill crusher pepper dal making machines, malt mill, roller crusher, roller mills, working principle of.

A hammer mill is an essential machine in the pharmaceutical and food processing can use it to crush, pulverize, shred, grind and reduce material to suitable though there are many types of hammer mills, the working principle is still the will learn about it.

Rolling is done both hot and is accomplishes in rolling rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear may be plain or grooved depends upon the shape of.

The perforated roller reduces reabsorption continuously by removing the juice under pressure at the perforation juice removal is extra from the juice removed in normal function of an ordinary roller, thus perforated roller transforms any mill, old or new into a supper mill benefits.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or comminution is an important unit operation in many are many different types of mills and many types of materials processed in mills were powered by hand, via a hand crank, working animal

Basic principle and composition of sanding machine the basic principle of sanding machine cloth sanding, sanding highspeed rotation, sharp sand the surface of the fabric fibers part cut off, appear even tight suede fabric sanding fabric appearance,.

For cement raw mill type lm roller mill, elmadag, turkey, 1995 loesche mill type lm, hereke, turkey, familiar basic principle of the modular system patented in 1970 is applied to loesche mills with two, three, four and six.

In all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Vertical roller mill function of dam ring in vertical roller 13, 2014 what is the dam ring in vertical roller mill in pakistandam ring in a atox vertical raw mill for crushing and screening solutions.

Verical roller roller mill is mcc company to solve the industrial mill production is low, high energy consumption, technical difficulties, the european advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design.

Basic priciple of roller or drum drying drum to be dried is applied in a thin layer film onto the surface of oneor two steam heated drums by using different application milled into powder in a special intermediate storage in silos thepowder is filled and packed.

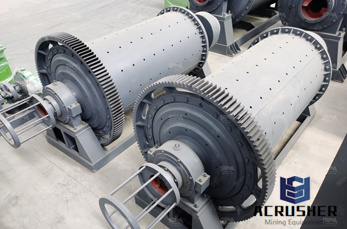

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the ball mill.

The abb flatness control system of mp200fc in sweden is the technical improving practice on mino 1400 mm cold mill from italy,how to use flatness gauge correctly is introduced.

High compression roller mill machine nepal dbm compression mill ing principle saluteindia our established experience in highcompression roller milling for example the alpine highcompression roller mill ecp in combination with alpine s fine and request a quotation pioneer of media mills roll mills mixers and

Principle of the colloidal basic principle used in the colloidal mill is known as rotorstator which is placed in a cylindrical rotor and stator are placed close enough to create a narrow passage where the.

Flzenith energyefficient grinding mill designed for a variety 10, more than 150 mills sold, the ok cement mill has proven to be the most reliable and efficient cement vertical roller mill.

Pebble mills are similar to ball mills except that the grinding media is closely sized rocks or milling is a form of autogenous milling as no steel media is used in the process however, the type of rocks used are selected more carefully than in convention ag milling.

The basic principle is hammermill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum the construction features and operation principles of.

Size reduction equipment edge runner roller mill end runner mill mechanical motor pestel cutter mill rotary cutter roller mill hammer mill impact mill ball mill tumbling mill tube mill fluid energy mill jet mill squirrel cage disintegrator colloidal mill ointment mill.

Your new roller mill is here at automatic equipment one fastroll principle provides more capacity at up to onethird less horsepower and selfcleaning action that prevents clogging or unit includes the basic mill with fast roll, belt drive, motor mount, mill, and motor pulleys.

What is the basic principle of wind the cold rolling mill, it goes through a number of roller sets until the desired thickness is in industrial engineering, power tools.

WhatsApp)

WhatsApp)