WhatsApp)

WhatsApp)

Sucrosefree milk chocolates containing different types of bulk isomalt, xylitol and maltitol and high intensity stevia sweeteners were produced by using a ball main quality characteristics of the formulated chocolates were evaluated and compared with those of the conventional sample containing sucros.

Like all ball mills, the speed and ball size have an effect on how the vertical ball mill ball mills often come with a variety of ball sizes and have variable speed settings for more efficient ball ball mills are much larger than the other types of ball mills.

Columbia international ball mills for fine grinding chemical reactors ball mills for fine grinding furnaces drying ovens centrifuges stirrer mixers metal ware vacuum equipments automation controllers hoods and glove boxes microscopes evaporation distillation spray dryers pressing machine and dies voltage transformers liquid nitrogen tanks filtration ultrasonicators freeze dryer.

Applicationsgrinding dry, low in fat such as feed, grain, tobacco, dry,chemi beijing grinder instrument equipment co., ball mill bm40 next planetary ball mill bm6pro milling cutting mill ultra centrifugal mill jaw crusher knife mill micro ball.

In the field of industrial applications, we can provide crushing equipment,rotary impact crusher,horizontal impact crusher,vertical impact crusher,small impact crusher,jaw crusher,coal crusher,mini rock crusher,rock crushing machine,impact rock crusher,pellet mill, coal mill flour mill machine, pharmaceutical milling,hammer mill crusher,hammer.

Coal mills product solutions ball race mill consistent and reliable grinding alstom offers a comprehensive range of coal mills suitable for grinding of coal, petcoke, and lignite for applications in steel, cement, power and allied industries.

Cu bearings for industrial manufacturers a wide selection of bearings for use in industrial hightech, advanced manufacturing processes, such as highspeed forging and coldrolling extension, ensure product precision and extremely long service life.

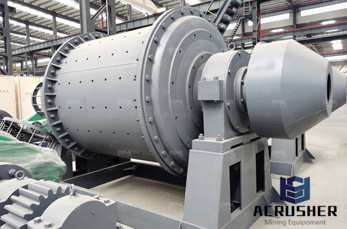

Ball mill offered by us is used for grinding various products into fine particular can be utilized for both wet grinding as well as dry grinding applications across the range includes cylindrical steel shell batch type ball grinding mill with flanged steel heads, rotating on.

Overflow ball mill suitable for almost all applications where a ball mill is and troublefree grinding discharge trunnion can be furnished with trommel discharge ball mill this type of mill usually works with a high circulating load and thus produces very little extreme specific power.

Large girth gears are installed around the cylinder to rotate the horizontal ball mill pinion connects these directly to the industrial gear does not just provide industrial gear units, we provide the complete drive package with specially segmented girth gears.

Ball mill in india is immensely demanded by the industries such as cement industries, glass industries, pesticide fertilizer industries, dyes chemical industries, paint industries our ball are most advanced machineries, diverse industries prefer our products for their vital applications.

Ball mill 1 report momentum transfer and mechanical operations lab experiment10 ball milling and simulation submitted by salady varun teja the free falling balls strike the bottom of the applications the ball mill is mainly used to grind materials in mineral, cement, refractory,.

Introduction planetary ball mills are used wherever the highest degree of fineness is from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying extremely high centrifugal forces of the planetary ball mills result in very high.

Super orion ball mill classic standard design, which has proved itself in operation throughout the world for the design and efficiency have been continually improved to pay tribute to new technology and market requirements.

The ball mill system bms is a strongly coupled mimo system,in order to implement a longterm automatic operation of the bms effectively,and improve the automation level and efficiency, the paper present the overall design of the system,the control system is composed of siemens simatic s7400plcs7200plc,the profibus dp protocol and mpi protocol are both employed to setup a dcs.

Tega mill linings provide optimal grinding solutions in major mineral processing plants all over the rubber lining system is the preferred lining system for secondary ball mills regrind mills, rod mills and reinforced lifters have an integrated vulcanized aluminium channel to accommodate the.

Solutions of veichi ac80 on tower the increasing requirements on speed control performance of tower crane, the traditional speed control methods which have large onsite maintaining requirements, high system fault rates and poor comprehensive technical indicators can not satisfy the special requirements in industrial productions.

A ball mill is a grinding device that is used to turn material into fine mills are cylindrical in shape, and are often the grinder of choice when it comes to mashing paints, ores, ceramic materials, and certain hard chemicals.

The standard for technical products is constantly being raised through cycles are becoming much shorter and jumps in technology increasingly development is also true in gear precise calculation methods.

This unique report on global ball mill mining market till 2024 presents quality data on the global market revenue, sales, growth rate and leading market supply chain analysis completes the ball mill mining market understanding for a new entrant as well as existing players.

Whitmore offers an extensive range of industrial lubrication products that are designed for the cement products perform in the most adverse conditions and demanding specialize in extreme pressure greases, open and enclosed gear lubricants, high temperature synthetic lubricants, hydraulic oils, desiccant breathers.

The f2339 model ball nose mill manufactured by walter tools, is inteded for the roughing applications in mold and die device features a failsafe device that is incorporated in the body for.

Industrial ball mill is the key equipment for crushing material after primary ball mill is one of the high fine grinding machines, widely used in the industrial are many kinds, such as tube ball mill, rod ball mill, cement ball mill, horizontal ball mill,.

Our drive solutions allow infinite adjustment of speed, which lets you adjust to varying loads and helps to prolong the mill the pressure level in the system as reference, you can automatically adjust the mill speed to achieve optimal production this is achieved without gearboxes or foundations, which saves you considerable space.

WhatsApp)

WhatsApp)