WhatsApp)

WhatsApp)

Ball Mill | Working of Ball Mills . MIKRONS Ball Mill form a significant class of equipment used in the field of size reduction. The slow rotational speed combined ...

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry ... but the working principle is the same as for ball mills.

From ZENITHgrinding mill FAQ, you can get more information about maintenance, installation of ball mill, Raymond mill, vertical mill, trapezium mill etc.

We come to talk about control measures of noise of ball mill. After our previous analysis, considering that only affect the normal functioning unit.

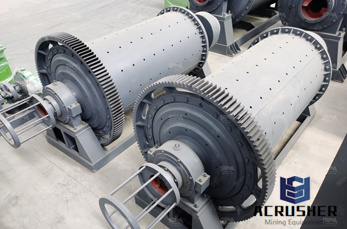

Grinding in Ball Mills: Modeling and Process Control ... The mill is driven by a girth gear bolted ... The design of a ball mill can vary significantly ...

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal ...

There are some quantity index in the overview of the working principles of ball mill. Grinding operation is a further processing for the crushed product.

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotat...

How Can Determine the Working Speed of Ball Mill? ... The Working Principle Of Cement Mill Cement Mill Plant bypass, clinker cooler, cement and coal mill, ...

Ball mill is widely used in many industries, such as black metal, nonferrous metal mining section, nonmetal mines, construction, electricity, coal, traffic, light ...

Working principle; Technical data; ... According the materials and discharging method, ball mill can be divided into dry type ball mill and wet type lattice ball mill.

Judgement of ball mill working condition in combined grinding ... in the ball mill has an ... the ball mill working condition can be judged so the ...

co mill working principle. Advantage working principle of horizontal mill ... Ball mill,Ball mill working principle,Ball Mill products,ball mill price ...

Jun 19, 2015· Video embedded· https:// Learn about Ball Mill Critical Speed and its effect on inner .

Working. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30 ...

How I built a homemade, quick and easy ball mill, that can also be used as a rock tumbler. How I built a quick and easy ball mill

According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in. ... Ball Mill Working Principle

ball mill working principle. Previous ... We can IMPROVE ALL PLANTS / Mineral Processing Engineering LABORATORY Ore Testing. 911Metallurgy Engineering.

working of a ball mill. working of ball mill drawing. How can you design of ball mill The QA wiki Answers Ball Mill is widely used in metal and nonmetal mines ...

Ball Mill Introduction Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement ...

Video embedded· How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

BASIC PARTS, CONSTRUCTION, PRINCIPLE AND WORKING OF BALL MILL Basic parts. The basic parts involved in the ball mill are as follows: The metallic cylinder which is ...

A ball mill can also be helpful in the process of ... Professionals should be proficient in their maintenance skills when working on these types of ... FAB 3R. All ...

How can ball mill working in your production line?Ball Mill is crucial equipment for grinding after materials are crushed. It is an efficientmachine for grindi.

WhatsApp)

WhatsApp)