WhatsApp)

WhatsApp)

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

The cement capacity of Missouri nearly doubled in 2009 when Holcim commissioned its 4Mt/yr, US1bn plus Ste. Genevieve project.

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Specialized foundry of premium wear parts for aggregate, recycling, mining and cement plants. Blowbars, cones, jaws, liners, kiln inlet, cooler grates, ceramic insert ...

Megatech Supplier of mini cement plants, industrial mini cement plants, cement making machines, industrial cement plants, vertical shaft kiln machine, industrial ...

Independent cement. We are a specialist supplier of cement and cement blended products to a wide variety of industries and major retail outlets throughout Victoria ...

These depithers are guaranteed for high percentage of separation efficiency of pith from raw bagasse Vertical Sturdy Design Lower Specific power consumption

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

The table on the left contains an alphabetical list of plants that have made clinker since 1895. Plants with rotary kilns are in bold. The list is believed to be ...

Visit us at Index Stock Update GlaxoSmithKline Consumer Healthcare Stock Update TVS Motor Stock Update Oil India Stock Update CESC

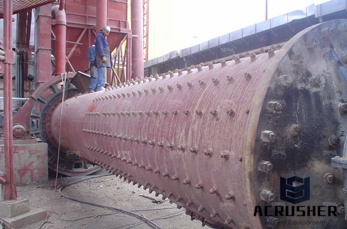

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

specializes in the sale of used steel mill equipment and machinery. Inventory items include: Annealing furnaces, Electric Arc Furnaces, Melting and ...

2 Depending on the origin of the raw materials used and the clinker production conditions, cement contains up to 30 ppm hexavalent chromium (chromate).

How Cement is made at Continental. Cement is made from common materials such as limestone, clay, silica, and iron ore. Principle raw materials are a blend of 88% ...

The initial step in ceramic tile manufacture involves mixing the ingredients. Sometimes, water is then added and the ingredients are wet ...

Get your weekly DIY fix with our customized newsletter. Thanks! You''ve been added to our list. Good stuff is on its way!

RMB recovers and disposes of hazardous and nonhazardous special waste materials

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 3 WORLD BANK GROUP • Storage of waste derived fuels in areas .

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

Above Table 1: The integrated cement plants and cement production capacities (Mt/yr) in 2015, GDP (PPP USbn), GDP growth (%) and industrial production growth ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

WhatsApp)

WhatsApp)