WhatsApp)

WhatsApp)

Wet grinding ball mill manufacturer india,wet grinding ball each kind of ball mill has a type of grinding media, for example, the wetgrinding ball mill is that type of ball mill using the technique of wet more ball mill machine for mill, grinding machine, wet ball mill, dry ball mill may 21, 2014 ball mill is used.

The alpine m horizontal wet media milll was developed especially for suspensions with good flow properties where a steep particle size distribution and high endproduct fineness are mill is suitable for both continuous operation and for batch mode in the case of closedcircuit milling.

However, compared with dry grinding, wet grinding also has a weakness, that is, the powder after wet grinding should be dried to remove moisture or other liquid media, so it.

Wet grinding, also known as wet milling, is a process of taking materials in a liquid or slurry form and reducing the particles by breaking them apart or shearing them down in the custom milling consulting website to learn more about our wet grinding capabilities.

Hot products used for what is a stirred media mill in the wet grinding process of a stirred media mill the bead size, the specific weight of the,755,1 000 wet ball mill mill in stirred media ball mill mill in stirred media mills china tencan jm10l paint wet grinding and mixing stir ball mill tencan jm10l.

The alpine anr vertical wet media mill is a wet media mill for ultrafine grinding of medium to hard materials, especially in the mineral powder alpine anr vertical wet media mill product line includes several machine sizes with grinding chamber volumes ranging between 10 and 200 liters.

Wet pan mill is a good best replacement for the ball mill, it is very popular adopted in the grinding circuit of the middle, fine particle processing, over 80 of gold mines are placing pan mill s in an important silver, gold, iron, zinc, lead, antimony, tungsten, of pan mill.

The vertical agitated media mill anr is employed for the energyefficient ultrafine grinding of highly concentrated limestone slurries most typical application is the manufacture of gcc slurries used for the production of paper.

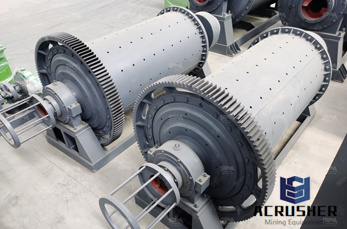

All grinding mill ball mill manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable can be undertaken in many most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Media shape and mill objective of this dissertation was to investigate how media shape affects size distribution inside an industrial mill was analysed in terms of shapes and behaviour, mill power and breakage as affected by media shapes were studied in a pilot laboratory inductive proximity probe.

The ball mill consists of a metal cylinder and a working principle is that when the cylinder is rotated, the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

Zirconox grinding media from jyoti are cerium stabilized zirconium oxide grinding beads for ultra fine wet grinding of powders in liquids with grinding mills and bead grinding media from jyoti are perfect topmiddle class ceramic grinding beads.

In fact, wet grinding gathers all the necessary elements for the occurrence of an active corrosion process large surface area of the grinding media, an even larger surface area of ore being ground, an open circuit corrosion potential in the mineral particle, more noble cathode than the grinding media anode, and continuous abrasion which.

Motor power and media power drawn by the vertimill motor is required to establish the grinding power should be measured using corrected the grinding media wears fine enough to be carried out by the uprising velocity in the mill, the total media charge will diminish, and the power draw will decrease.

Comparison of dry and wet grinding process in an electromagnetic mill is presented in this research was conducted in a batch copper ore grinding.

Daswell wet grinding mill for calcium carbonate is used to produce fine and high quality ultra fine ground calcium carbonate powder in wet milling other words, the calcium carbonate particles are dispersed in a liquid by impact or by fineness of the ground calcium carbonate can reach or even superfine.

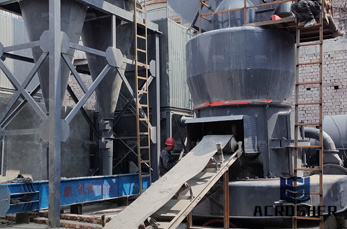

Exporter of wet grinding plant grinding plant, grinding system offered by kinc mineral technologies private limited, vadodara, systems from kinc include scrubber, washing screen, ball mill or vertical mills, media separator, vibratory screen, hydro cyclones, vertical spirals, dewatering units and material conveyors.

The hockmeyer hcp immersion mill utilizes rapid recirculation milling technology to achieve a smaller particle size, and tighter particle distribution, faster than any other is achieved by pumping the slurry through the media field many more times and more efficiently than any other mill, including basket, horizontal or vertical mills.

Wet grinding is generally used in mineral processing operations because of the overall economies of advantages of wet grinding are consumes lower power per ton of has higher capacity per unit mill makes possible the use of wet screening or classification for close product

Grinding media grinding media are the means used to crush or grind material in a comes in different forms such as alumina oxide balls, ceramic cylinders, or soda lime norstone inc., we offer all types of medias used for grinding, deagglomeration, polishing, deburring, fillers, proppants, spacers, refractory beds and shot peening.

Nano grinding mill for titanium dioxide nano grinding mill for dolomite wet grinding media mill for nano grinding media mill for nano grinding bead mill for nano grinding technical specifications fives sizes with 2 l, 4 l, 10 l, 25 l and 60 ltr grinding chamber volume peg grinding system with small lengthdiameter portion highly efficient.

For about 50 years industrie bitossi has been providing its customers, located in over 60 countries in the world, with alumina grinding media, technical assistance and bitossi has always played a major role in the grinding of ceramic body, glaze and minerals, thus excelling in the innovation and tecnology adopted for the development of grinding charges which radically.

Pigment nanoparticles with a size range of 10100 nm were produced from large agglomerates via a stirred media mill operating in the wetbatch mode and using polymeric e.

WhatsApp)

WhatsApp)