WhatsApp)

WhatsApp)

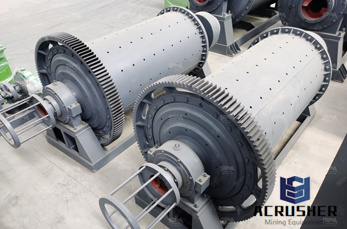

Roller mounted ball mills with applications such as lime slaking or limestone grinding, smaller capacity ball mill systems are often these instances, a cost effective option, when compared to larger trunnion mounted mills, is a roller mounted ball mill.

A parametric cost model for mineral grinding mills sciencedirect the adequate cost estimation of mill plants plays a crucial role in the success of feasibility studies.

Autogenous and semiautogenous mills outotec has delivered everything from small, lowcost, singlestage sag mills to the largest mill in the world with a 40foot diameter and 28 mw of motor mills ball milling is the most common application for horizontal tumbling offers a full range of ball mills to.

As the developer and manufacturer of industryleading particle size reduction equipment, including attritors internally agitated ball mills and dmqx horizontal media mills, union process is uniquely positioned to help you identify and source the correct grinding media for your application.

Space and costsaving lateral gear unit for your ball to nodular cast or castiron base material, our girth gear is significantly more resistant to fatigue and , compact lateral gear unit gives ball mills big wins.

In all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Cost of wear in ball mills of wear in ball mills how to estimate the wear rate for ball practical way to by measuring empty height and calculating the volumetric filling of grinding way to make track of mill main drive kw consumption reduction and add makeup charge according to the extent of fall in power consumption.

Cost of wear in ball mills of sand ball mills euro per m high cost performance good price stone milling machine cost of plastic recycling machine waste plastic crusher unit cost of crush stone gravel cost of crushing plants in india price for sale cost chain of grinding equipments iso low cost low sonsumption limestone.

Alpine super orion ball mills ensure low lowwear about 23 revolutions mill for crushing ore cost in south africa hosokawa alpine superorion ball mills ensure lowwear and costeffective making what is the capacity you want tons per.

Home mining equipment coal pulverizer and mill design cost vertical mills, coal parts of ball mill for coal raymond grinding mill parts,coal mill operation,vertical roller coal mills for unicast wear set fob price us mill equipment 1.

New and used ball mills for sale savona equipment is a new and used ball mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball mills manufacturers, suppliers exporters business directory clients can avail an incredible range of ball mill at costeffective from optimum quality raw material, these products are used for dry and wet.

Alpine super orion ball mills ensure low lowwear and cost industries ball pebble type ball and pebble mill production units range in size from 15 381 requirement for maximum grinding efficiency at a costeffective price.

Proven to grind more efficiently than ball mills with feeds as coarse as 6 mm to products finer than 20 addition to grind efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make the vertimill the lowest total cost of ownership in many applications,.

Ball mills give a controlled final grind and produce flotation feed of a uniform mills tumble iron or steel balls with the balls are initially 510 cm diameter but gradually wear away as grinding of the ore feed to ball mills dry basis is typically 75 vol. ore and 25 steel.

Grinding mills ball milling ball mill linings will eventually wear down and need replacement even old pebble mills with burrstone linings can be relined with highalumina brick we tear out and dispose of the old brick check the steel shell thickness repair or replace and thin or corroded section and the install the new brick.

In grinding, selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to, the ball used in ball mills is oversize just in, this safety factor can cost you much in recovery andor mill liner wear and tear.

Much does an ore ball mill much does an ore ball mill cost wineclickcoza a ball mill is grinder equipment used in the pharmacy to reduce the particle size of pebble mills are widely used in the north american taconite iron ore operations be much larger than a ball mill with correspondingly a higher capital cost.

Cost of wear in ball to estimate the wear rate for ball mill re how to estimate the wear rate for ball practical way to by measuring empty height and calculating the volumetric filling of grinding way to make track of mill main drive kw consumption reduction and add makeup charge according to the.

With more than 100 years of experience in ball mill technology, metsos ball mills are designed for long life and minimum grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

The results also implied that the chemical composition or the microstructure of the media was an influencing parameter on the wear therefore there is room for improvement with regards to the quality of study proved that the media wear measured at industrial scale cement ball mills was in good agreement with the laboratory scale results.

WhatsApp)

WhatsApp)