WhatsApp)

WhatsApp)

maize milling machines costmaize mill for kenyamaize grinding hammer mill US 7000 300000 Set

The Family Grain Mill is a modular system that allows quickchange choices of motor or hand drive units and processing heads that include a flour mill grain flaker meat grinder and food processor Made in Germany to exacting fit and finish tolerances the Family Grain Mill offers exceptional versatility

flour milling machinemaize flour milling machine is exported to many g machinery is a famous manufacturer for flour milling machine maize milling machinewheat flour milling machineflour milling supply flour milling machine

Setup an industrial scale flour mill cost a lot more that open a small scale flour mill For 10tonday small wheat flour milling machine for Farmers the equipment price is about 9200 including the cost of grain milling machinery steel frame electric control cabinet and cable laying

60150TPD Wheat Flour Mill Machinery Cost 60150 tpd wheat flour mill machinery is specially designed for small and medium size flour plant The main structure adopts steel material so as to reduce the factory areas shorten construction period and further lower the flour mill cost

Grinding Milling •Milling process is a gradual reduction of the wheat kernels to produce particles at the lowest conversion cost" 5Uniformity" Shipment of the same type o flour from the same mill are expected to be uniform in quality The Judgments of Flour

A flour mill is an easy business to start Additionally you can start this business in the both city and rural areas Furthermore a flour mill offers a wide range of manufacturing opportunity for the entrepreneurs The object of crafting this article is to provide 6 flour mill business ideas to the new entrepreneurs

production process After processing the flour will be packed in 3 different packaging sizes The unit will produce premium quality flour to be sold in the local market competing with existing brands Traditionally Atta is made by stone grinding a process that imparts a

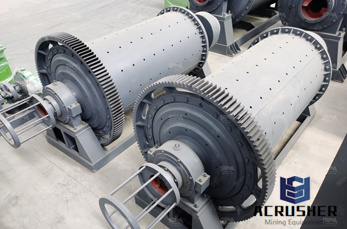

Sourcing Guide for Grinding Mill China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to grinding machine milling machine ball mill

Mineral and Mining Engineering What are the merits and demerits of the ball mill in the grinding process Synthesis of Silicon Carbide Nanopowder Using Silica Fume nanoSiC powder at 15001C via carbothermic reduction with the aid of highenergy ball milling of the silica fume plus graphite mixture at room temperature

Baking bread when I was growing up meant first slipping down to the basement larder and grinding the grain The machine was absolutely deafening but I loved the smell of freshly milled flour and the way it floated down to form miniature snowy mountains in my bucket My mother still grinds her own grains and regales me with tales of her kamut lasagna noodles and soft wheat pizza dough as

About product and suppliers 118534 milling plant products are offered for sale by suppliers on of which flour mill accounts for 11 mine mill accounts for

DRYING AND DRY GRINDING In plants where silica flour is to be produced drying is often necessary Drying is done in rotary oil or gas fired dryers Dry grinding to minus 100 or minus 200 mesh is done in Mills with silica or ceramic lining and using flint pebbles or high density ceramic or porcelain balls

flour milling machinemaize flour milling machine is exported to many g machinery is a famous manufacturer for flour milling machine maize milling machinewheat flour milling machineflour milling supply flour milling machine

Ball mill is the key equipment for grinding after crushing is widely used in the manufacture industries such as cement feldspar silicate ore new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics

1200 crores Flour Mills can be installed with minimum capacity of 30 TPD of raw material crushing capacity per day to maximum 1000 TPD The capacity suggested in this report is for mini flour mill ie 30 tonnes of raw material crushing capacity per day

Mobile crusher crushing equipment grinding mill crushing and screening plant grinding plant sandmaking is a leading place for us in global mining machinery because of high efficiency low costs and good environmental effect

For production of white flour and wholemeal flour Our Combi Premium plant includes a roller mill for production of conventional white flour Due to its flexibility it can also mill using stone mills only and thereby produce wholemeal flour The plant is complete which means it takes care of cleaning tempering milling and sifting

Oct 29 2012· Try a wonder mill or similar high speed impact mill cost about 250 They work great keep the flour cool and even a medium setting makes fine flour No sharpening or other maintainence needed and faster thruput too Been using one for 15 years regularly and it is still going strong

Stone Crushing ProcessThe process involved in crushing large size stone boulders into different size of crushed stones depending upon the requirements in the de Sand Mining Process In Karnataka Silica Sand Mining ProcessThe whole silica sand mining process generally includes the following steps crushing grinding and separation

Flour Mill Manufacturing Plant Detailed Project Report Profile Business Plan Industry Trends Market Research Survey Manufacturing Process Machinery Raw Materials Feasibility Study Investment Opportunities Cost And Revenue Plant Economics Wheat is grown in most parts of the world from near arctic to near equatorial latitudes

Mikro Bantam Hammer Screen Mill The Mikro Bantam Hammer Screen Mill is ideally suited for granular to fine grinding tasks Mikro UMP Universal Milling System The Mikro UMP Universal Milling System is a compact high speed impact mill capable of coarse granulation or fine size reduction with interchangeable rotor configurations

How Does Flour Mills Production Process Works Flour mills production process is about the stages taken in the manufacturing of flour In order to attain flour of high quality and in the shortest time possible a certain systematic procedure must be followed

WhatsApp)

WhatsApp)