WhatsApp)

WhatsApp)

In order to ensure that the position accuracy of the ball mill components is not changed greatly the base of the ball mill should adopt the whole block structure A ball mill can be installed on top of the concrete base when its compressive strength is up to more than 75

The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics Bond Work Index bulk density specific density desired mill tonnage capacity DTPH operating solids or pulp density feed size as F80 and maximum ''chunk size'' product size as P80 and maximum and finally the type of circuit openclosed you are designing for

mini ball mill a ball mill base is design and fabricate to withstand the weight of the rotating ja r motor and gears After a few hou rs stop the mini ball mill and the powder can b e filtered

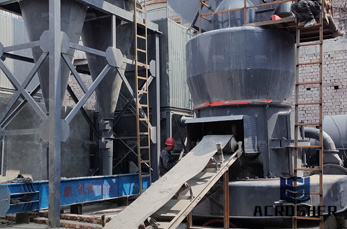

A ball mill is one kind of grinding machine and it is a device in which media balls and solid materials the materials to be ground are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it is easy to operate and so they are widely used

ball mill base designe eindhovensestudentenraad base design of heavy ball mill ore dressing equipment base design of heavy ball mill ore dressing equipment offers 1339 wet milling equipment products About 30 of these are mine mill 10 are grinding equipment and 8 are mill

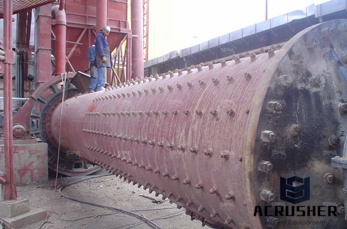

The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media ceramic or metallic balls or rods the product to be ground is added and the cylinder is put into rotation via an external drive causing the media to roll slide and cascade

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills dry basis is typically 75 vol ore and 25 steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones

Ball mill base designe stone crusher machineall mill base designe stone crusher machine visicom equipment design equation ball mill stone crusher machine4 results mill grinding a mill is a dev that breaks solid materials equipment design equation ball read moretone crushing machine used in copper ore mining plantet p chat online

Apr 07 2011· The wooden base will serve as the support for the ball mill It can be made by resting the wooden platform on top of the two 1"x10"x4" 254cm x 254 cm x 1016 cm pieces of wood Place one smaller piece on either end of the platform and screw them in

Nov 18 2008· My Tech Report on Ball mill ball mills batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of the input material and the nature of the output which I need We discuss the types of ball mill the basic principles of the ball mill how it works the details of design including

【 Ball mill manufacturer 】 With more than 35 years of experience in grinding balls mill technology JXSC design and produce heavyduty scientific ball mill with long life minimum maintenance among industrial use laboratory use Besides portable ball mills

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both the mills and the grinding jars allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistry

Mar 29 2019· The wooden base will serve as the support for the ball mill It can be made by resting the wooden platform on top of the two 1"x10"x4" 254cm x 254 cm x 1016 cm pieces of wood Place one smaller piece on either end of the platform and screw them in

The Design of Ball Mill Control System Base on TwoCell Immune Controller on ResearchGate the professional network for scientists Get Price ball mill grinding machine designe – Grinding

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size

Ball mills are simple in design consisting of horizontal slow rotating vessels half filled with grinding media of ¼" to 15" The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition

Ball mills With more than 100 years of experience in ball mill technology ''s ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications both in open or closed circuits

Mar 14 2007· Personally I would base any preliminary design on previous experience In the case of something like this and lacking previous experience I would not be willing to do a preliminary design As an engineer who has experience using FEM for the design and assessment of SAG and ball mill foundations I know that this approach can be time

Chapter 3 Steady State Model Development and Validation OoCities of the steady state models is required as they are the foundation of the is arguably the only one that is widely used for design pilot mill scaleup and Dynamic models of the SAG mill ball charge rock charge water charge and mill

The ball mill method was first invented by Shimadzu in Japan in 1924 Nowadays a great variety of mill designs are in use but the basic principles applied by Shimadzu remains the same The ball mill process is based on solidphase reactions and operates within the temperature range between 70 and 180°C

May 30 2016· This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend raw

The ball size is often in the diameter range of 2075 mm The biggest size is chosen when the mill is used as a primary grinding mill For fine grinding of eg sands balls can be replaced by cylpebs which are heat treated steel cylinders with a diameter of 1240 mm and with the same length as the diameter

WhatsApp)

WhatsApp)