WhatsApp)

WhatsApp)

Fiber cement installation cost has become more competitive in recent years as more siding contractors become familiar with fiber cement and start offering installation Expect to pay 900 – 1400 per square foot for the installation based on the level of expertise of the installing crew and the complexity of the job

Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine typically gray powder comprised of calcium from lime silicates aluminates argillaceous and ferrites with addition of sulfates Cement plants can operate continuously

In view of this is the production cost of the Cement Plant Project high In fact once the Cement Plant Project is put into operation although the production cost of the early investment is a little high but the recovery cycle is short generally 12 years can recover capital of course also from the following aspects to save production

Most projects limit millings to no more than 30 percent of the volume of the new mix There are other uses for millings such as on driveways or on less traveled roads How to Install Asphalt Milling for a Driveway Hunker

These tables show the average lowbid unit prices for individual bid items used in highway construction and highway maintenance projects The data is organized statewide and by district and the averages are based on 3 consecutive months and 12 consecutive months

Aug 30 2012· This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale fly ash mill scale and bauxite

100tpd cement grinding unit project cost100tpd cement plan project cost 100tpd cement plan project Processing Feldspar can be a useful raw material that is widely used in glassmaking ceramics and infrequently used like a filler »More detailed More Detail cement grinding unit project report in india

For all commercial pavement projects we are the paving crew you can count on to offer superior value and quality pavement services Road Milling Whether your asphalt road has begun to bleed rut ravel or any other form of damage we at Finley Asphalt and Concrete are able to take on your road milling project

Jun 26 2017· Learn about Milling Stabilization and Pulverizing and how they can be used on your paving project 3 Asphalt Processes to Know Milling Pulverizing and Stabilization Wolf Paving uses several techniques when it comes to their Asphalt paving projects

100Tpd Cement Grinding Unit Project Cost Request a quotation 100tpd Cement Plan Project Cost– Rock Crusher MillRock 100tpd Cement Plan Project Cost is a leading global manufacturer of crushing and milling equipment 100 tpd slag cement grinding unit project cost

In Adeloye 11 the unit cost of fuel component for cement production is as low as 6 per tonne in China as opposed to 30 per tonne in Nigeria this has contributed largely to the high and persistent rise in unit cost of ce ment production

Our asphalt milling contractors are ready to help restore the look and function of your paved surface The asphalt material removed during milling can be reused for other projects at a reduced cost Recycled asphalt can sometimes be used as an alternative to stone gravel and hot asphalt It is also resistant to harsh weather elements and is

raw milling cement project cost Cost of 100tpd cement plant 100 tpd cement plant project cost in south africa SAM 100 tpd cement plant project cost india » grinding units upto 2000 tpd plants Get Price And Support Online 400 tpd cement plant project cost in india 50 tpd mini sugar mill

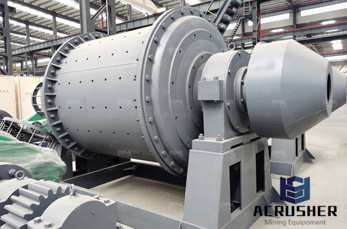

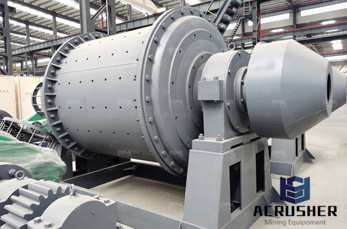

Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills roller presses typically in combination with a ball mill and clinker pregrinders with ball mills

Cement Clinker Grinding Plant price Many people have a certain understanding of the Cement Clinker Grinding Plant They all know that the equipment is a kind of equipment for fine powder production of various ores industrial materials construction materials limestone etc and the models of the equipment are many and different

Cement plant project cost is relatively large For example maintenance costs are high The choice of maintenance policy and the quality of maintenance have a fundamental impact on mini cement plant project cost Our project report on cement plant includes vibrating feeder jaw crusher impact crusher cement ball mill lifer preheating

Chinese Mining Crushing Milling Equipment Gold Ore Separator Machine In South Africa Energy Requirements For A Rock Crusher Bay State Milling Co Wingold Mobile Crusher Plant For Sale In India Bauxite Ore Crushing Equipment For Sale Crusher Used To Mine Copper Cement Ball Mill Price And Cost What Is The Main Mining Machinery Supplier In

12 Cost Control Monitoring and Accounting 121 The Cost Control Problem During the execution of a project procedures for project control and record keeping become indispensable tools to managers and other participants in the construction process

Raw Milling Cement Project Cost Cement Effect Raw Wall What Are the Raw Materials in Cement Cinder Raw Material Raw Concrete 4004 Raw Concrete Cement Raw Materials Caesarstone Raw Concrete Honed Raw Cement Flooring Raw Concrete Exterior What Is Portland Cement Raw Cement Quartz Countertops Dark Grey Raw Cement Finish Cladding Natural Stone to Raw Concrete Smooth Raw Concrete

Development of 6Roller UBE Vertical Mill for Slag Cement Grinding 211 Comparison of Specification and Cost of Mill Table1 is a Specification Comparison of Conventional newly Developed Mill performance improvement target of this project the new mill ran at lower vibration as expected

project cost of mini cement plant in india YouTube Feb 15 2016 Mini Cement Plant Process On the basis of the above concept 50 tpd mini cement plant project cost Mini Cement Plant Project Cost gaytripackagingcoin Mini Cement Plant Project Cost in IndiaMini Cement Plant Process Crusher Mini Oil Mill Machinery oil shale crushing plant

Project calculates cost totals when ratebased resources resources that have peruse costs and cost resources are assigned to tasks The resources'' Accrue at setting will have an impact on this Changing the standard rate for a resource affects the cost of tasks that are 100 complete and that have the same resource assigned to them

In the cement production line producing 1 ton of Cement need grind at least 3 tons of materials including raw materials fuel clinker mixed materialsgypsumGrinding operation consumes about 60 of total power in cement plants raw material grinding more than 30 while coal mill used in cement plant consumes 3 cement grinding about 40

WhatsApp)

WhatsApp)