WhatsApp)

WhatsApp)

In one form or another, the cnc milling process is involved in the vast majority of tangible products in modern industrial it only directly makes a small fraction of parts, its the most common method to create tooling, so its difficult to avoid altogether.

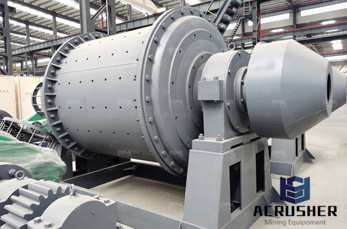

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the process was developed by benjamin and his coworkers at the international nickel company in the late of 1960.

The modern milling process is a gradual reduction of the wheat kernels through a process of grinding and millers skill is analyzing the wheat and then blending it to meet the requirements of the end science of analysis, blending, grinding, sifting.

Wheat milling is the process by which wheat is ground into are the steps of wheat milling process the wheat milling process involves separating the wheat grain into its constituents that is the germ, bran, and follows the steps, wheat milling is more complex than is conveyed by this simplified view.

Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by mill is charged with media small beads or spheres and activated by a highspeed agitator shaft to separate the individual particles.

Milling of cereal grains is a very important process for cereal and feed is accompanied with starch granules damage, starch crystalline structure disruption, and starch molecules change, and therefore performance of the finished products is subject to milling process.

A physicsbased material processing simulation was approached to reveal the distortion law of aerospace monolithic components due to milling basic principle of restart analysis was expatiated,and its completed system frame was milling.

Abrasive machining is considered a mechanical process like milling or turning because each particle cuts into the workpiece removing a small chip of typically used to improve the surface finish of a part, abrasive machining can still be used to shape a workpiece and form features.

offers 10,744 maize milling process 5 of these are other food processing machinery, 1 are flour, and 1 are oil wide variety of maize milling process options are available to you, such as haccp, iso, and fda.

Wheat milling the wheat milling process starts the wheat must first be remove any ferrous metal objects, stones and other foreign of air remove the dust and new colour sorter separates impurities from wheat by color and so reducing the overall product waste and improving flour quality.

The milling process definitions cutting speed,v c indicates the surface speed at which the cutting edge machines the or true cutting speed, v e indicates the surface speed at the effective diameter dc value is necessary for determining the true cutting data at the actual depth of cut a is a particularly important value when using round insert cutters.

The flour milling process begins with cleaning the grain and tempering it by adding tempered grain is ground in a series of rollermills to remove the bran and to cut the each rollermill cycle, the ground grain is sifted and separated into various material is sent to a purifier, or shaking sifter.

is as fundamental as drilling among powered metal cutting is versatile for a basic machining process, but because the milling set up has so many degrees of freedom, milling is usually less accurate than turning or grinding unless especially rigid fixturing is implemented.

milling a machine operation in which a work part is fed past a rotating cylindrical tool with multiple machine types peripheral milling slab, slotting, side and straddle milling up milling conventional down milling climb facing milling.

Ball milling process and its effect on hydrogen adsorption storage of mwnts the ultrafine ws2 powder was obtained by a improving solid phase synthesis method which is shown in chapter 3 of.

cnc milling the computer translates the design into instructions on how the drill needs to move to create the, the drill can move up down, or tilt at an angle, and the table moves the part complex parts, the part may need to be rotated at some point in the milling process.

This presentation details the development, understanding, and scaleup of an aseptic crystallization, which utilizes a novel wet milling during antisolvent addition approach, that consistently delivers desired physical properties that result in an acceptable uniformity of.

elsalam, in encyclopedia of food sciences and nutrition second edition, wet wet milling is a process that gives starch as the main product output in addition to several other products, namely, oil, protein, and process is a waterintensive technology as m 3 of fresh water per ton of corn is needed in modern corn wet milling.

Why kilning kilning is a hydrothermal treatment conducted on oats once the hull is have a high lipid content and the active enzymes make them susceptible to rancidity.

When the ion milling begins, secondary cu ions are detected by the sims detector as having a significant the milling process starts to punch through the cu top layer and into the sio2, the intensity of cu starts to diminish and the presence of sio2 is first detected and then starts to.

Milling process milling process milling process is a type of machining that allows modeling in complex forms and trimming pieces of several materials such as metal, wood, plastic, composites meanwhile the removal of chips and processing residues.

Combined with a virtual simulation system on end milling process and cutting force signal obtained in cutting trials, an optimal bp neural network model that can be used rapidly to predict vibration in end milling process is trained and established.

Finally, chip formation, stress distribution, cutting force, and milling temperature were, a series of milling experiments of ti6al4v were carried out to validate the simulation confirms the capability and advantage of 3d fem simulation in the complex milling process of titanium alloy.

The milling process grain needs to be milled before it can be used to make different the grains are then sieved and ground to separate the endosperm the white flour from the bran layers outside case of the grain and the wheat germ part that grows a.

WhatsApp)

WhatsApp)