WhatsApp)

WhatsApp)

Was to locate the variation of ball filling in the charge program abrasion in this section, ball abrasion was calculated via manufactures ball charge the time of this research, mill ball charged, feed rate, and average moisture were 7 tons ball size.

Ball mill feed size 25mm handling capacity h applications cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal.

With an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill, despite these benefits, applications of the vertical roller mill for cement grinding are less twocompartment ball mill operating in a closed circuit with a high efficiency separator.

The bonds standard ball mill is used to determine the work index value of differ ent bond work index is defined as the kilowatthours per short ton required to break from infinite size to a product size of 80 passing 100 the breakage characteristics of a material remain constant over all size ranges, the calcul ated work.

Ballrod mill literature the ballrod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizes.

Working into the mill through one or both bearing trunnions, the material is ground by impact and friction from the ground product is discharged from the mill through discharge slots provided in the mill tube, through a discharge wall or through the end trunnion.

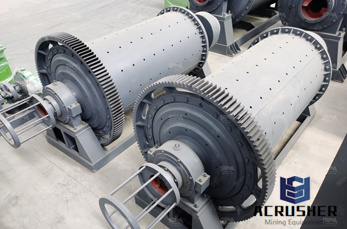

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size.

Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial the initial chargin of a mill, coghill and devaney 1937 defined the ball size as a function of the top size of the feed,, dv kf db ball size cm f feed size cm.

Energy saving ball mill product introduction a high efficiency and energy saving ball mill with rolling bearing capacity up to 160th product improvement cylindrical energy saving grid ball mill is lined grooved ring plate which increases th.

Mill performance is variables solids concentration, top ball size and slurry filling, were investigated using this methodology and according to simulated results an optimal operational condition was defined for vales industrial mill, corresponding to 25 mm of top ball size and solids concentration between 76 and 80.

Mine equipment mainly includes raymond mill, ball mill,roller mill, company,as a worldclass raymond mill manufacturer,.The feed ball mill operating weight.

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum,building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

The alpine so super orion bill mill is a durable milling device known for its low energy consumption and high level of paired with a hosokawa air classifier, the alpine so ball mill is capable of grinding many hard materials down to d80 2 m.

If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various mill produces 1 to 50 tonhr of powder and energy requirement.

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material feeders, and the system grinding process can also take place in dry or wet mass of feed in size class 1 is distributed in the lower size certain.

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic principle ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and.

Optimization of particle size and specific surface area of pellet feed in dry ball mill using central composite design of concentrate filter cake compared with wet the dry ball mill.

Ball mill working be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a.

Ball mill features cement ball mill ordinary cement ball mill for most of the ring flow grinding system, which is characterized by high grinding efficiency, mill production, power consumption, especially when the grinding slag cement, the performance is more prominent.

Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, to the need of customers, ball mills can realize both wet and dry mills have been designed in standard sizes of the final products between mm and mm in.

Pamir dry agitator bead mill the agitator bead mill for finest drygrinding compared to conventional ball mills, with the pamir it is possible to obtain extremely ne products combined with very high throughput capacities at low specic energy consumption.

The 12 principles of green chemistry prevention of waste atom economy less hazardous chemical syntheses design safer chemicals safer solvents and auxiliaries for.

Agsag mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball of the range of mill sizes available, agsag milling can often be accomplished with fewer lines than in a conventional rod millball mill diagram of types of agsag.

Ball mills operate either in open or closed circuit operation is best utilized when another stage of grinding follows the mill reduction ratio is small feed material is already fine and one pass through the mill produces the desired results product size.

WhatsApp)

WhatsApp)