WhatsApp)

WhatsApp)

quality parameters of cement mill quality parameters of cement mill. Get more info of silica sand mining process equipment for – Vertical mill parts AIA Engineering Ltd. Welcome to AIA Engineering/Vega Industries.

Ball Mill New Cement Plant In Lindi Tanzania | Crusher Mills clinker ball mill for cement grinding plant; ball mill design for ilmenite processing; difference between ball mill and hammer mill; ball mill features .Related Info... » Learn More

algorithm to detecting main parameters for cement mill, and then to judge the ... The Effect of ... Optimizing the operation of the cement mill | Industrial Efficiency ... Ball mills account for the majority of all mills in cement mills ...

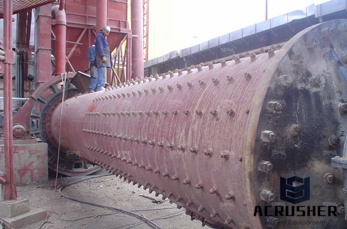

The cement mill Understanding Cement Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media ... Use of ball mill in cement industry YouTube Feb 15, 2016 . ball mill ...

Introduction Ball mill (also named grinding ball) is one of the most important grinding mills in the mining industry which is used to break all kinds of minerals and other materials in the industries of ore beneficiation, construction ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS EFFECT OF BALL SIZE DISTRIBUTION ON. MILLING PARAMETERS. François Mulenga Katubilwa. A dissertation submitted to the Faculty of Engineering and...

parameters affecting the ball mill operating – A study on the effect of process parameters in stirred ball mill. A study on the effect of process parameters ... Factors Affecting the Efficiency of Ball Mill – College Factors Affecting the ...

UltraTech Cement Limited The plant produces high quality cement with Grinding Mills, Japan, and ... The company prides itself in being able to meet superior quality parameters of... Get Price Advanced process control for the ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

importance for grinding cement As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different ...

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the twocompartment ball mill, commonly called the tube mill. Significant ...

parameters by signal measurements for an industrial ball mill Yigen Zeng and Eric Forss Malmberget. Three operating param eters were considered: the feed rate, the mill feed Chat Now The Parameters Of Ball Mill, Wholesale ...

grinding machine fitting . Grinding Machine,Grinder Machine,Grinding Mill,Roller Mill ... heavy industry is the best manufacturer of grinder machine which ... important parameters for belt conveyers . parameters of thread grinding ...

Operational Experience from the United States'' First ... Home>Case important parameters of ball mill> important parameters of ball mill. Ball Mill Loading ... Advanced process control for the cement industry . Coal mill is an ...

effects of grinding media shapes on ball mill. Comminution is an important Important Parameters Of Cement Ball Mill process in mineral processing, power plants, cement production grinding. Ball size distribution inside an industrial ...

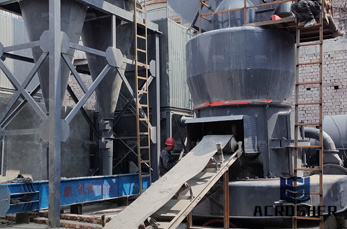

Vertical mill parameters is very important for the performance of vertical mill. Knowing the main control parameters of vertical mill can .

Roller Many materials can be ground in vertical roller mills such as: raw materials I ... The process is called a drying/grinding process, where most of the material/product is transported .... The mill parameters are supplier ...

Operational Experience from the United States'' First, the quality of the cement produced is extremely important in cement grinding and there, Traditionally, the closed circuit ball mill with high efficiency separator has been ...

effect of ball size distribution on milling parameters CORE Determination of milling parameters in each ball size interval. 100 ... As far as reliability and mechanical efficiency are concerned, tumbling ball mills are. Live Chat

Getting more from the cement ball mill with the Fives FCB TSV 3rd generation classifier*) Effizienzsteigerung bei der Zementmlung in der .

Correlations for the Grindability of the Ball Mill As a,, study of the effect of the various parameters on the performance of a ball mill, balls, time of grinding, particle density and speed of the ball mill (rpm) have been. Contact

of the cement leaving the ball mill. To reduce process deviations and to stabilize the grinding process, a modelbased predictive conRequirements For Optimized Control To optimize the energy consumption of the mill, Siemens ...

WhatsApp)

WhatsApp)