WhatsApp)

WhatsApp)

A 25MW 150t ball mill makes its way from Murrin Murrin to Kin Minings Leonora Gold Project Credit Kin Mining The owners of a new gold mine near Leonora say it remains on schedule to open this year as construction of the mine''s 15 milliontonneayear processing plant begins to take shape

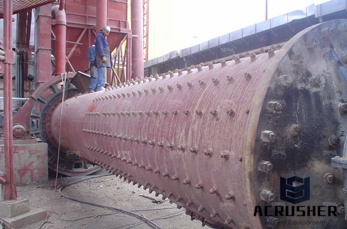

CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding for continuous or batch type operation in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings

The Ball Mill Abrasion BMA test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills It gives accurate predictions of the service life of wear resistant alloys

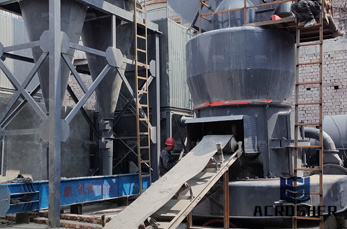

Ball Mill Ball mills are used primary for single stage fine grinding regrinding and as the second stage in two stage grinding circuits According to the need of customers ball mill can be either wet or dry designs Ball mills ha Read More Gold CIP CIL Plant

BRAND NEW HARD ROCK MINING equipment available for immediate sale from Mt Baker Mining and Metals We are a USA manufacturer located in Bellingham WA Call us today at for more information 3''x6'' Ball Mill 1TPH complete with drive 20hp motor balls frame

Our Gold Stryker GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons of 45 inch rock in a day all the way down to 300 mesh through the mill to release the gold Perfect for the small gold mining operation

The jaw crusher has been a staple of the hardrock mining industry since its invention It is used as a primary crusher for all types of ores The jaw typically takes the larger run of mine product and produces a sized discharge for feed to a secondary crusher such as a cone crusher ball mill or hammer mill

well the mill customer is working to maximise the benefit For operations that have undertaken such an exercise in finer improved fragmentation for the mill''s benefit the mine rarely is willing to return to the old ways of costminimised blasting The reason is that the mine also benefits greatly from more consistent fragmentation with less

Overflow Type Ball Mill A ball mill with simple structure Production capacity 017~170th Product Improvement Wet type overflow ball mill is lined with Xinhai wearresistant rubber sheet with excellent wear resistance long service life and convenient maintenance

Determining mining and reclamation project costs Establishing baseline prices for appraisals The Cost Guide Covers Capital and operating costs for more than 3000 items of mobile portable and stationary equipment commonly required by mining and milling operations Following is a partial list of equipment types included in the Guide

This is a fully operational Gold Mine where Cal Mining has been producing Gold for several years from this property The Oatman Gold Roads areas have been producing Gold for over a hundred years Check these statistics from Addwest Minerals at the near by Gold Road Mine

how gold mining with a ball mill works transportbielen ball mill mining crushing grinding mining ball mill overview ball mill is an efficient tool for fine powder grinding the ball mill is used to grind many kinds of mine and other materials or to select the mine

Gold Stryker GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation The Gold Stryker GS7000LD uses a large 25 HP Honda Industrial engine for many years of trouble free use

The ball mill is very similar to the SAG mill except it has a larger proportion of steel balls to assist in the grinding process Following grinding in the ball mill the material is returned via the sump 8 to the secondary hydrocyclone 9 for resizing

The operating principle of the ball mill consists of following steps In a continuously operating ball mill feed material fed through the central hole one of the caps into the drum and moves therealong being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls

DOVE Ball Mills are made of high – grade cast and carbon steel for extra strength long and troublefree operations Warranty Program All DOVE equipment carry a 2 years 24 months standard Manufacturer Warranty which can be extended to 5 years in addition to lifetime spare parts supply service

Every mining operation requires sophisticated gold room in order to ensure the highest recovery of gold production To this end DOVE supplies and manufactures a complete range of equipment instruments tools and accessories which includes Gold Concentrating Table Gold Centrifugal Concentrator melting furnace crucibles ingot molds

Intermittence Gold Ore Ball Mill Reliable Operation Xinhai provides mineral processing technology equipment manufacture and onestop service for mineral processing plant which solve many problems for mine investors Xinhai equipment mainly include ball

Ball Mills Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100 years They are proven workhorses with discharge mesh sizes from 40M to 200M Use of a ball mill is the best choice when long term stationary milling can be justified by an operation

Energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as Gold ore Cooper ore Magnetite ore Antimony Calcite Kaolin Mica Clay Bentonite etc Ferrou metal or Nonferrous metal materials

If the peripheral speed of the mill is too great it begins to act like a centrifuge and the balls do not fall back but stay on the perimeter of the mill The point where the mill becomes a centrifuge is called the Critical Speed and ball mills usually operate at 65 to 75 of the critical speed

WhatsApp)

WhatsApp)