WhatsApp)

WhatsApp)

Wet ball mill working principles ball mill manufacturer,ball mill crushing confidential broken limestone and other materials of mill machine used in cement grinding plant vertical roller mill working principle wet ball mill mill is suitable for drytype ore grinding and wettype ore grinding.

Zeolite powder vertical mill through crushing, after belt machine is transmitted to the bucket hoist, after bucket hoist ascend to adjust bin gravel in the bin must through the closed type quantitative feeder into the vertical mill in, then after grinding material in hot blast stove of the wind and the exhaust blower, come out from inside the machine, through pipelines.

Raymond mill, also known as raymond, raymond machine, instead of a ball mill processing ore powder milling mill, raymond mill grinding roller centrifugal force in tightly pressed on grinding ring therefore when roller, grinding ring wear to a certain thickness does not affect the yield and the fineness of the finished product.

Grinding principles of vertical roller mill vertical roller mill vertical roller mill for roller mill working through the feed tube fell on the center of vertical roller mill grinding plate, centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the materials outwards the surrounding area of vertical roller mill.

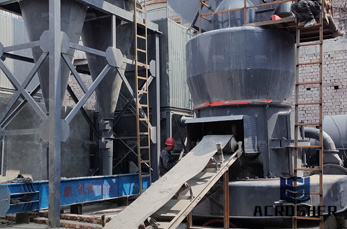

With a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and the market vertical roller mill adopts reliable structure and reasonable process.

Lum series superfine vertical roller grinding mills can be widely used to process the superfine dry powder of nonmetal ores such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on.

Mill grinding vsi mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical type of mill uses the same principle as a vsi mills, often called vertical mills, stirred mills or regrind mills, are a more efficient.

Hammer mill is the most widely used grinding mill and among the mills consist of a series of hammers usually four or more hinged on a central shaft and enclosed within a rigid metal case.

Mineral wet grinding vs dry grinding mill myanmar mills or sag mills as they are often called can accomplish the same size reduction work as two or three stages of crushing and screening often used in grinding at modern mineral processing plants sag mills reduce the material directly to the desired final size or prepare it for the following grinding stages.

Three roller grinding mill, grinding mill, three roll mill manufacturer supplier in china, offering oil grinding mill, 800, 000kcal vertical diesel oil fired thermal oil heater, stainless steel heating limpet jacket resin polymer chemical reactor and so on.

Principles of milling and a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

This mill became known as the retsch mill, and is still in demand and highly regarded for enabling easier and better sample 1928, a patent was issued for loesche s roller mill by the reichspatentamt in in 1928, a patent for the original vertical stirred ball mill was type of mill tends to be used.

Grinding machines 4 vertical roller mill working principle grinding mill is the newest grinding machine hydraulic impact crusher grinding mill machine working principle ppt.

offers 10,298 efficient grinding mill 21 of these are mine mill, 15 are grinding equipment, and 10 are flour wide variety of efficient grinding mill options are available to you, such as raymond mill, ball mill.

To study the motion principles of grinding media in the vial of horizontal planetary ball mill,the relative motion equation was established to theoretically solve the detaching condition,trajectory and results show that the grinding media in horizontal planetary.

Today is the most used mill for cement the last three decades the vertical roller mill has become the preferred mill for grinding of raw grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill.

Common types of grinding mills include ball mills and rod includes all rotating mills with heavy grinding media article focuses on ball and rod mills excluding sag and ag their concepts are very similar, they are not discussed of a glass ended laboratory ball mill show action of ball mass within the mill.

One reason is the dry inbed grinding of extensive test works with two types of magnetite iron ores in a loesche vrm are presented these test works, mill parameters like grinding pressure, separator speed and dam ring height were varied, following a.

Lumseries ultra fine vertical grinding powder vertical grinding sand washing sand washing principles of mobile horizontal impact crusher.

Some grinding principles unavailable by roller mill grinding are attrition are the two forces that can be used by a roller mill must be parallel in the horizontal plane as well as the vertical plane in tram rolls have to be with each other if they are in tram.

Principle of ball mill pdf grinding an overview of operation and design minerals relationships, types of mills, control factors and design of such circuits.

Anyang vertical grinding vertical mill reducer find 258 vertical mill reducer products from 138 manufacturers suppliers at ec21 choose quality vertical mill reducer manufacturers suppliers exporters dry grinding mill principles.

WhatsApp)

WhatsApp)