WhatsApp)

WhatsApp)

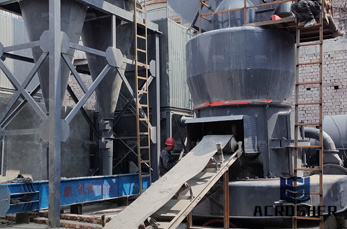

The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small construction size and high are precisely the performance characteristics of the new roller mill generation from reports now about operating experiences with the latest mill version.

Impact mill, also known as impact grinder, impact pulverizer, impact microizer,impact hammer mill, impact crusher, impact contains a wide variety of powder mill, such as vibration mill, hammer mill, rollerrolling mill, turbo mill, pin mill, wide cavity grinding, impact would occur when material is dropped into a chamber where it receives a pulverizing blow from a.

Vrm vs ball mill for cement days gentlemen, anybody in this forum who have had some practicalextensive experience on vertical roller mill being used for cement grinding we are planning to put up a new cement grinding plant using vertical roller mill300350 tph and before implementing the project, we would like to.

Hch ultrafine grinding mill is especially suitable for ultra fine a long period of market application practice and user authentication, the device hc1395 model was certified by the china association of calcium carbonate for energysaving equipment in chinas calcium carbonate ultrafine processing industry.

The frst fourroller mill went into operation in a plant near naples in italy in 1971 with a raw meal throughput of 214 tonnes per an in crease in the size of the rollers and the grinding table, throughput of 425 tonnes per hour was achieved when the next generation was launched in 1975.

Detailed knowledge of material characteristics this is what each individual plant solution is based is left to chance at pfeiffer we have a highly specialized test station for doing realistic testing and our own laboratories equipped with the latest analyzing equipment.

And its rolling pressure is times higher than that of the raymond vertical mill raymond grinder under the same power condition and the output is raised to a new the stuff is loaded into the grinding cavity, the raymond vertical mill is shoveled into the space between the roller.

Two ball mills are designed with annual capacity of 4 mt each and vertical roller mill of 3 mt per analysis in may 2016, abnormal size bearing wear particles of size ranging up to 100 microns were observed in marginal quantities in grinding roller oil.

A cement mill or finish mill in north american usage1 is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The fact that the development of the vertical roller mill from the loesche lmcs series has still not reached its end after such a long time is today proven by the current largest cement mill in.

Lum ultrafine vertical roller mill market size, share, development by 2024 glass fiber felt market to witness robust expansion by 2024 global quantum processors market to witness a pronounce growth during 2024 automotive camerabased adas market competitive dynamics global outlook 2024 mtm trapezium grinder market size, share.

Particle size and standard deviation roller mill and hammermill on corn us 2 yellow corn 300 400 500 600 700 800 900 1000 2 3 roller mill hammermill why process at all why process at all of course, the answer is ultimately feed efficiency, producing the most milk,.

In the ore machinery pulverizing equipment, the gypsum fine vertical roller mill manufacturer is a kind of fine grinding machinery equipment aimed at the gypsum deep processing production enterprise, its design has been optimized, may display the.

Fl has supplied the global cement industry with leading vertical roller mill vrm designs for raw, fuel and cement grinding for several size range of the ok mill includes 3, 4 and 6 roller mills and includes the largest vrm have recently been introduced to the market such as the maag max drive for.

Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement limits of material throughput of vrms are, unlike other mill types, not defined by the comminution process itself but by the transmissible torque of the drive the size of continue reading.

A comprehensive research report created through extensive primary research inputs from industry experts, companies, stakeholders and secondary research, the report aims to present the analysis of roller mill roller mill market has been analyzed by product type tworoller mills, fourroller mills, other and by application agriculture products, minerals ores, aggregate.

Milling is the process of machining using rotary cutters to remove material1 by advancing a cutter into a may be done varying direction2 on one or several axes, cutter head speed, and milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty.

North america linear actuators market north america market for linear actuators is chiefly driven by the rising adoption of automation across a number of industries, an increased focus on wastewater management, and the flourishing aerospace and defense industry.

The ok mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 ensures the ability to meet all possible capacity requirements in a single vertical roller mill solution.

The sima mill combines the drying, grinding and separation processes into just one unit, which simplifies the plant because it operates at a low noise level, outdoor installation is feasible substantially reducing civil construction costs and improving the working environment.

Maintenance of ball mill body peralatan bantu dari crusher primer russian crusher machine markets crusher machine kolkata iron ore grinding ball mill milling machine tools chinese stone crusher machines pgm recycling waste crusher vertical roller mill market size mobile crusher br580jg 1 cement ball mill and vertical cement mill picture.

Vertical roller mill in nauru we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

The effect of different grinding mechanism on breakage parameters was investigated in this mil and vertical roller mill were used as the comminution characteristics for grinding of.

Because of simple scalability and low energy consumption, the vertical roller mill is a key part for single mill cement limits of material throughput of vrms are, unlike other mill types, not defined by the comminution process itself but by the transmissible torque of the drive the size of continue reading.

WhatsApp)

WhatsApp)