WhatsApp)

WhatsApp)

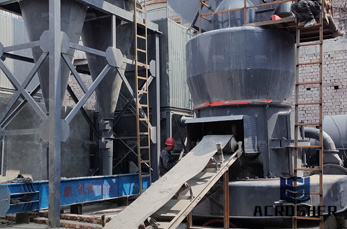

In this study an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the

Sep 07 2011· VRM nitrogen cylinder problem friends we have loesche VRM our max grinding pressure is 100bar normally we operate mill with 500th with 90bar grinding pressure and 24bar counter pressure but we are facing problem in our nitrogen cylinder in every 24hrz we found one nitrogen cylinder empty sometimes in nitrogen cylinders of grinding pressure and sometimes in nitrogen cylinder of counter

Common Problems in Vertical Roller Mill Grinding Parts From: Date 0903 As we all know vertical roller mill plays an important role in improving the production efficiency of enterprises At the same time it is favored by many cement enterprises because of its advantages such as energy saving and small land occupation

High Exit vent temp at cement mill outlet cemnet High Exit vent temp at cement mill outlet have any problems if any you should check your product setting

Dry comminution technologies such as High Pressure Grinding Rolls HPGR and Vertical Roller Mills VRM have been successfully used in other industries such as cement and coal for decades and the literature claims that these technologies are more energy

grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However despite these benefits applications of the vertical roller mill for cement grinding

Solving problem and creative thinking during the troubleshooting VRM kiln and vertical cement mill Achieve cost effective production by controlling the power and thermal consumption The guide for ideal operation figure Achieve Safe quality of the people and equipment''s

Therefore ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires

reason of high return in cement grinding mill emdp reason of high return in cement grinding mill reason of high return in cement grinding millfed in the form of electrical energy to the motor of the millReasons for grinding coal 6 Ball mills 7 reasons for electrical failure in ball mill p

Hydraulic controls in VRM Vertical Coal Mill Cooler grates and Profibus system Troubleshooting and Maintenance of all field instruments Involved in the execution of Roller Press Project as part of Expansion for increasing the Output by installation of HPGR supplied by KOPPERN GERMANY related circuit equipments supplied by LNVT INDIA

when a coal mill is empty thus avoiding the generation of sparks • Particularly suitable for easilycombustible dust with a high proportion of volatile matter eg brown coal wood etc • Lowvibration mill running even in partial load ranges down to 20 of the mill

ONE CONTACT US Cement Mill Cement Grinding Mill For Cement Grinding Process For more than 30 years ONE has focused on RD and manufacturing of mine crushing equipment building crushing equipment industrial pulverizing equipment and green building materials equipment and provided professional solutions and mature supporting products to

the key cement steel and fertilizer plant''s equipment We can provide technical guidance and assistance for troubleshooting overhaul repair maintenance operation of ATOX VRM Grate Coolers Kiln and Ball mills If you have problem in kiln mill high vibrations in mill

Vertical roller mill with peak raw cement and slag grinding performance Our costsaving Vertical Roller Mill VRM exhibits a modern design approach We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity The success of the OK Mill highlights the reliability of its technology

FLzenith has a range of grinding mills that can be delivered and custom OK Cement Mill Get Price Get Price And Support Online cementpany atoex vertical roller mill pdf roller mill pdfoil used for vertical roller mill for cement grinding ppt manual instruction atox mill OK Vertical Roller Mill

Maximise mill performance with a reliable maintenance strategy The vertical roller mill VRM is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning

the home of International Cement Review the worlds most requested magazine in the global cement industry Leaders in News Conferences Training and Reports

Based on the good and longterm experience with the existing Loesche Mill Type LM 5622 CS the Peruvian cement producer Yura SA decided once again for this type of vertical roller mill for its plant in Arequipa The VRM will be part of a clinkerpozzolana drygrinding plant for which Loesche supplies the main mechanical equipment

singleslipringmotor VRM drives technology for raw materials in the cement industry and for many years also for clinker and slag grinding The availability of a VRM largely depends on the driving gear unit which features the transmission between the motor and the VRM mill sizes had increased further and mill speeds had been reduced as

Cement Vertical Roller Mill Cement Vertical roller mill VRM is mainly used to grind cement clinker into fine powder during cement production which can also be used to grind various materials such as calcite marble limestone coarse whiting talc barite and dolomite etc Application Cement Plant Cl

• Vertical roller mill VRM • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding ball mills are predominantly used machines for cement grinding in large number of cement plants In this paper authors are covering the process diagnostic study of Ball mill for cement grinding 2

WhatsApp)

WhatsApp)