WhatsApp)

WhatsApp)

Outotec Grinding Mills Optimize grinding mill performance efficiency and availability to ensure you meet your plants operational targets Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency mechanical reliability and maintainability

the ball mills It was expected a loss on mills performance as predicted by grinding tests showed on Figure 8 Figure 8 Comparison to standard charge and balls scraps Thankfully the performance of the vertical mill was still better than the ball mills which reinforces the use of this technology

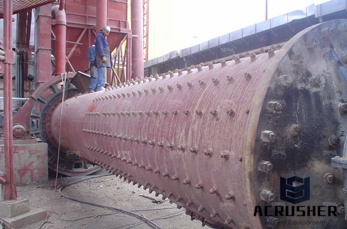

Hardinge Conical Ball MillMineral Processing Metallurgy Grinding can be done either wet or dry and on account of the Conical shape of a Hardinge Mill a positive discharge can be obtained without the use of internal screens such as are employed with practically all high speed pulverizers and machines of the ordinary ball mill type

Used Ball Mill Copper Ore For Sale Henan Mining Ball mill ball mill direct from zhengzhou jinmaigh efficient and quality ore ball mill for sale 250000 min order the ore grinding equipment copper grinder ball mill with good performance 300000 set 1 set min order new style harga zirconia ball mill jar bekas grinding media high More Details

It is therefore proposed that the grinding rate ratio is a direct measure of the relative overall breakage efficiency of the environment of the plant ball mill Ball Mill Circuit Functional Performance Equation The above described parameters for system breakage and classification system efficiency factor the overall task of the ball mill circuit into its two distinct basic functions namely fines generation and

Good Performance Wet Gold Ore Grinding Ball Mill For Mineral Processing Plant Find Complete Details about Good Performance Wet Gold Ore Grinding Ball Mill For Mineral Processing PlantWet Gold Ore Grinding Ball MillGood Performance Ball MillBall Mill For Mineral Processing Plant from Mine Mill Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory

First ball mill ball has higher hardness and higher HVE value in order to resist the grinding of hard abrasive grain Second ball mill ball has enough toughness KI to resist impact and crack propagation Third ball mill steel ball has good anti fatigue ability in order to resist the effect of alternating stress and impact fatigue wear

With the assistance of latest technologies our experts have successfully designed Grinding Mill There are varieties of Grinding Mill available like Jigger Shoe link Leg Bearing Driving Pulley Grinding Plate and others Procuring the material from trustworthy vendors the outcomes are ready to

Good Performance Cement Plants Cement Ball Mill Grinding Equipment Find Complete Details about Good Performance Cement Plants Cement Ball Mill Grinding EquipmentCement Grinding PlantCement Ball MillCement Grinding Equipment from Cement Making Machinery Supplier or ManufacturerHenan Bailing Machinery Co Ltd

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of

Good performance cement plant used ball mill ball Good performance cement plant used ball mill ball grinding mill p US 6000 12000 Set Building Material Shops Construction s Energy Mining New Ball from Zhengzhou Huong Machinery Equipment Co Ltd on Alibaba

Improving knowledge of grinding technology and mill operations to operate optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production raw meal grinding coal and pet coke and finish cement grinding Improving the competences of the team plays a key role in the optimal utilisation of the

Ball mill in cement industry crushersliming ball mill in cement industry cement as the essential building materials to the construction industry keep a good state of development new cement clinker grinding plant using the most simple process and conven China cement ball mill pinion gear suppliers

a Mill Geometry and Speed – Bond 1954 observed grinding efficiency to be a function of ball mill diameter and established empirical relationships for recommended media size and mill speed that take this factor into account As well mills with different length to diameter ratios for a given power rating will yield different material retention times the longer units being utilized for high reduction ratios and the

Moulding processpouing when the molten iron temoerature reaches 1500 Cusing the teoperature difference between moletn iron and the this waythe ball can achieve internal organization of grain refinement and be hilethe carvide is radially arranged and such carbide is embedded in the matrix again during grinding processforming hatd layer continouslyso that the

Quality ball mill grinding supplier on sales from ball mill grinding manufacturer – find China ball mill grinding factory suppliers from Jinan Zhongwei Casting And Forging Grinding Ball CoLtd of page 27

The Continuous Ball and Pebble Mill grinding units range from 24 610 mm diameter to 96 2438 mm diameter and from 36 915 mm long to 360 11 m long PATTERSONs unmatched Ball and Pebble Mill custom design experience and manufacturing capability is your assurance of a system that meets your requirement for maximum grinding efficiency at a costeffective price

Ball mill grinding media 20150mm good material high hardness HRC6065 B2 steel round bar High Performance Forging Grinding Rod Dia 20mm 90 mm Carbon Steel Grinding Rods for Rod Mill In Mining and Cement Plant Contact Address LejiaPuji

Barite Grinding Mill Price Wholesale Barite Grinding High Energy Ball Milling Barite Grinding Mill Hongji Ball Mill is a key equipment to grind the crushed materials which is widely used in the manufacturing industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics

There is no general allpurpose ball in our product range because there are no generic processing plants The size of grinding media plays a key role in overall performance of the grinding circuit Larger grinding media has a smaller grinding surface area but offers a

China Good Performance Grinding Mill for Mineral Machine Find details about China Mill Ball Mill from Good Performance Grinding Mill for Mineral Machine Qingdao Epic Mining Machinery

Considering tumbling ball milling the variation of fraction of mill filled with balls and powder mill diameter mill speed media size and shape ball density ore type and feed particle size distribution as well as material properties affects the rate of breakage and overall mill performance

The Ball Mill Abrasion BMA test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills

Boll mill grind capacity calculation v grinding in ball mills is an important technological process applied to reduce the an important characteristic of capacity cement ball mill grinder mqg dec 12 2016 the ball mill is a principles of the grinding process ball mill in mouth and high production capacity more

WhatsApp)

WhatsApp)