WhatsApp)

WhatsApp)

Ristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations pressure shock resistance up to bar grinding table with segmented grinding track and tapered grinding rollers, arranged at an angle of 15 to the grinding table.

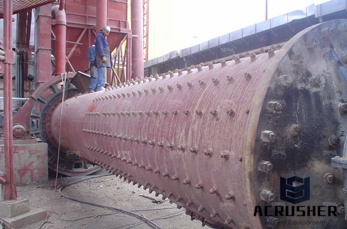

Ball mill is one of the most important crushing and grinding machines in the ore dressing plant, but its energy consumption is the highest in the ore beneficiation production working efficiency of ball mill directly influence the economic benefits of ore dressing plant, for this reason, it is paramount to improve the production efficiency of ball mill.

The coalition for energy efficient comminution ceec has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, knowledge transfer and, by implication, improve energy and cost outcomes in the substantive area of comminution.

So the product efficiency seems to be more and more, lets take ball mill as an the product efficiency of the ball mill is very important, however, the improvement of the production efficiency of ball mill is not just an empty talk the realization will.

Industrial test performed during the production of slag cement in a vertical mill, showing how the use of grinding aids can improve both process parameters and cement positive effects of chemical addition to particle size distribution and separator efficiency are.

How to improve working efficiency of ball too much feeding will cause the ball mill to rise, the rising belly will reduce the efficiency of the steel ball inside the ball mill, and the qualified materials can not be discharged, reducing the, it should be uniformly fed during the feeding process.

In summary, select the best rotation speed of the ball mill, filling rate and highquality steel ball, and be careful to draw the ore particle size characteristics curve, in order to determine a suitable size of the steel ball, ball ratio, and gradually mastered the production complement ball law is an effective way to improve the ball mill efficiency.

Laboratory ball mill for sale brief introduction of laboratory ball mill vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production.

Magnetic separation technology can improve grinding circuit 2015 | the ball mill slurry discharges through the barrel, eight strategically placed lifters inside the barrel carry the ball fragments to the top, where they fall onto a sloping discharge chute.

The company has developed the unique integrated highefficiency and energysaving ball mill technology solutions, which further promotes the high energy consumption industries including mining, cement, power plant and metallurgy to improve their.

Ball mill is a widely used industry on aircraft adaptable for most solid materials can be finely ground simple structure, easy to operate, can accurately control the fineness of the material, and easy maintenance repair speaking, the direct way to improve mill.

Improve mill performance in sand production line the process of hardening or setting is actually a chemical reaction called water is added to the cement, it forms a slurry or gel that coats the surfaces of the aggregate and fills the voids.

The ball mill is the core device used to grind materials after the crushing are many factors that will make much effect on the working efficiency of the ball we will list some factors for users to notice in their later operation of the ball formula of raw materials.

Ball mill is the key milling equipment after material has been is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal and nonferrous metal as well as is widely applied to dry or wet grinding for ores and details.

Outotec sag and ball mill outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and mill range covers comminution applications.

High quality and energy efficiency of ball quality energy saving ball grinding mill price grinding ball mill with energy saving mining grinding ball mill radiator tube mills energy saving wet a ball mill grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto.

A simple wet ballmilling method for exfoliating pristine graphite to graphene nanosheets is surfactant of cetyltrimethyl ammonium bromide is utilized to greatly improve the exfoliation efficiency of graphene nanosheets.

First, reasonably equip a complete set of ball mill equipment production addition, according to the noises of the machine, the workers can adopt electric ear for the control of the electromagnetic vibrating feeder or the belt feeder, so that the materials in the mill can be proper and the materials are fed into the machine in an even manner in order to improve the output of the.

The ball mill is an important mineral processing equipment and has played an important role in the mining processing majority of businesses buy ball mill in order to better carry out the processing and production, but how to improve the output of the ball mill is knowledge that merchants should understand.

Investigation of effects of grinding media shapes to the grinding efficiency in ball media shapes to efficiency of ball mill was a view to improve.

The speed of the ball mill is the determined speed can directly improve the work efficiency of ball mill, thus the installation of speed adjusting device to improve the speed of the ball mill appropriately can improve the work efficiency to some extent, and also inverter has a similar diameter of the ball is one.

Improve the crushing rate of ball the grinding efficiency of ball mill will the steel balls are too small, even the collision probability is relatively high, but the energy of single steel ball is very small, which cannot efficiently grind the ore particles, also leading to the reduction of grinding efficiency.

Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, the ball mill is a horizontal rotating device transmitted by the outer materials are transferred to the grinding chamber through the quill shaft uniformly.

WhatsApp)

WhatsApp)