WhatsApp)

WhatsApp)

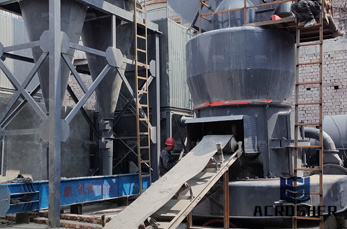

Sag mill ball mill locked charge drop charge frozen charge liquid resistance starter lrs introduction a "locked charge incident" is referred to by svalbonas 2002 as a "drop charge" while measuring the electrical currents between the motor rotor and the liquid resistance starter Details Wound Rotor Motor And Ball Mill Starting Curve

Lrs tanks in cement mills kift ball mill is mainly used for grinding various ores and other materials lrs tank cement plant standard milling workpiece size in vertical milling operation lrs for ball mill starmarineservices what is lrs in ball mill gr

Jun 25 2011· Dear all kindly suggest for a suitable starter to start a ball mill with 2600 kw 1000 rpm 11 kv slipring induction motor has any latest technology invented to start the motor other than LRS

In my experience SAG Mills are normally variable speed and Ball Mills are normally fixed speed There are multiple ways to provide variable speed the common ones are WRIMLRSSER or SCIMVSD the top of the range is gearless mill drives

equivalent ball or tower mill The high intensity means short residence times preventing overgrinding and giving a sharp product size distribution » IsaMill advantages 7 Horizontal Design plug˚ow design This avoids short circuiting and makes the mill far less sensitive to process disturbances The horizontal design allows the mill

Genmitsu CNC Router Bits Ball Nose End Mill Solid Carbide Nano Blue Coat Tungsten Steel 2 Flutes 6mm Shank 25mm Radius 50mm Cut Dia ideal for Wood Acrylic Soft Metal Aluminum 5 price 13 49 SpeTool Ball Nose Tapered Cone End Mill 14 inch Shank with 025mm Ball HRC55 Tiain Coated for CNC Carving and Engraving Bits 3 price 21

A variable speed medium voltage drive system from Ingeteam was set to drive the SAG mill including an MV transformer MV frequency converter and an MV squirrel cage induction motor For the ball a fixed speed solution was chosen with an MV WRIM wounded rotor induction motor with an LRS liquid rheostatic starter

BALL MILL DRIVE MOTOR CHOICES The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 per hour This type twocompartment mill is a

lrs acronym ball mill About Contact Inquirylrs acronym ball millMill grinding A mill is a device that breaks solid materials into smaller piece What Is Lrs In Ball MillBall Mill Lrs Dippers In South Africa Ball mill price in IndiaBall mill manufacturers in India Read More Full text Like ball mills

LRS Arcing in Electrolyte At Tarkwa large current spikes were found on the ball mill motor rotors during some startups as shown in Figure 11 The mill motors had previously suffered severe damage of the slipring surface which

Prev ball mill lrs dippers in south africa Get Price ball mill manufacturer in south africa YouTube Aug 2 2016 Contact Us For Help solutions ball mill and jaw crusher in south africa crushing plant Get Price ball mill manufacturer in south africa YouTube

The process flow sheet at Newmont Boddington Gold NBG comprises primary crushing closed circuit secondary and tertiary crushing using High Pressure Grinding Rolls HPGR ball milling and hydrocyclone classification to generate a milled product with a P 80 of 150 µm The ground ore is then floated to produce a gold rich copper concentrate for filtration and sale to overseas smelters

what is lrs in ball mill liquid resistant starters on ball mills the early detection of liquid resistance starter The Mill Safe Start was commissioned at both the the SAG

ball mill lrs operation liquid starters for ball mills Drag equipment have ball mill fans air Generally LRS is used for Cement Ball mill it up to speed and » Learn More Machinery and Equipment buys and sell Used Ball Mills for mining and minerals applications as well as smaller batch mills for chemical applications

Lrs Acronym Ball Mill Photodesign Wallinger Cement mill lrs you tubes hat is lrs in ball mill ball mill lrs operationliquid resistant starters on ball mills the early detection of liquid resistance starter the mill safe start was commissioned at both the the sag and the ball mills at lrs for the motor enables get price lrs

With more than 100 years of experience in ball mill technology ''s ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications both in open or closed circuits

Lubrication System Lrs Mill Apponaug Christian School Speed cement mill motor is adjus le dentalbliss Mill Lubrication System 1 máquina mill motor starter lrs cgm grinding plantsui le starter for ball mill starting through speed mill motor fixed speed

Ball mill suppliers have adopted the same technologies to move beyond the traditional limit Erection itself is simple and a shellsupported mill does not require to be lifted for maintenance effect on the result of the simulation and more work is required on this The effect of LRS – Liquid Resistance Starter SER – Slip

LRS ie liquid rotor starter which is use for starting the slip ring motor generally ht motor IN THIS STARTER LIQUID IS THE MEDIA FOR EXTERNAL RESISTANCE WHICH IS HIGH AT STARTING AND ZERO AT FULL SPEED AND IT IS ONLY FOR STARTING THE MOTOR ONLY ON ANOTHER SIDE WE CAN CONTROL THE MOTOR SPEED BY SAME BUT

• No process control available via the mill speed • The power factor of the motor is low and changes depending on the load A power factor correction has to be considered • The WRIM LRS system is causing high transient torques during the startup Figure 5 The WRIM LRS is causing high transient torques during the startup

STARTING TORQUE AND TIME CONSIDERATIONS The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 per hour This type twocompartment mill is a state oftheart shell supported cement finish mill

WhatsApp)

WhatsApp)