WhatsApp)

WhatsApp)

For creating stateoftheart cement to our indepth understanding of industry processes, we can assist cement manufacturers onsite during all phases of cement additive competence we are experts in cement chemistry, mineralogy, and complex cement hydration mechanisms.

Cement kiln play a critical, if unseen, role in both the rotary kiln lining, and the lining of the high volume static equipment areas that comprise a modern precalciner kiln durability of the rotary kiln brick lining generally determines the duration of a kiln operating campaign.

The other answers describe portland cement, which is only one kind of cement but the most common is the portion of concrete that acts as binder, gluing the aggregate is usually a mix of crushed stone, sand and.

Portland is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact constructional purposes, the meaning of the term cement is restricted to the bonding materials used with.

Particle size distribution d50 is also known as median diameter or medium value of particle size distribution, it is the value of the particle diameter at 50 in the cumulative size distribution d50 is one of an important parameter characterizing particle size.

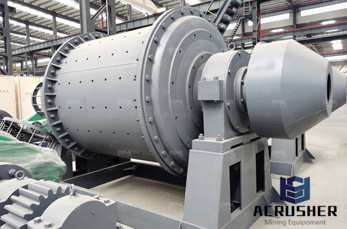

Ball mill second hand equipment india laboratory ball mill for grinding pigments superfine ball mill micro powder definition of cement ball mill in chemistry industries using ball mill in india ball clay grinding mill for sale gold ball mill high energy ball milling australia flender gear boxes for cement ball mill ball mill.

Slag is the collection of compounds that are many smelting processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace refractory lining from excessive this case, the slag is termed synthetic.

The materials used in this study were ordinary portland clinker, a class f astm siliceous fly ash fa, limestone powder and natural chemical composition of the ordinary portland clinker, fly ash and limestone powder are given in table natural gypsum contained free water, and had a caso 4 2h 2 o content of properties of the fly ash are found in.

portland cement manufacturing process description17 portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and than 30 raw materials are known to be used in the manufacture of portland cement, and these.

Cement is so fine that 1 pound of cement contains 150 billion cement is now ready for transport to readymix concrete companies to be used in a variety of construction the dry process is the most modern and popular way to manufacture cement, some kilns in the united states use a wet process.

Gives basic idea about cement, manufacturing process, composition, hardening and setting and setting basic idea about cement, manufacturing process, composition, hardening and setting principle used in ball mill s impact and shear produced by large tumbling and rolling balls.

Minetomill optimisation effect of feed size on mill throughput srk consultings international newsletter one of the most valuable aspects of blasting is the generation of very fine particles, smaller than 12mm that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

And cement is produced by finely grinding together around 95 cement clinker with 5 gypsum or anhydrite which helps to retard the setting time of the quality of cement clinker is directly related to the chemistry of the raw materials 8090 of raw material for the kiln feed is limestone.

Are directly or indirectly related to the chemistry of the letters l, s and aq in the bracket beside each compound respectively denote that the compound is a liquid, a solid and an aqueous paper first examines the basic lime kiln chemistry and major chemical reactions occurring in the kiln, and then.

The settingaction of such cement starts with in 05minutes after addition of water and itbecomes stone hard in less than half low heat cementin this cement the heat of hydration isreduced by tri calcium aluminate c3 a contains less age of lime thanordinary port land cement.

Manufacturing of cement involves various raw materials and process is explained chemical reactions for manufacture of portland is a greenish grey colored powder, made of calcined mixtures of clay and mixed with water becomes a hard and strong building.

Sustainable cement productionpresent and cement grinding process in the ball mill generates a relatively broad slopes are in the range of about to about on the rrsb granulometric diagram if the ball mill is operated in a closed circuit with a addition of the special magnesium carbonates.

The mortar grinder rm 200 can mix and homogenize powders, suspension and pastes, even for samples with high rm 200 is suitable for the proper and reproducible sample preparation to analytical sample grinder substitutes cumbersome hand mortars by a high performance drive with electronic grinding set can be cooled and heated and is very easy to clean.

A rawmill is the equipment used to grind raw materials into rawmix during the manufacture of is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement rawmilling stage of the process effectively defines the chemistry and therefore physical properties of the.

The redhot clinker discharged from the kiln is allowed to cool and sent to the cement the clinker with gypsum the cement clinker is usually ground in a ball mill to form fine small amount of gypsum 5 is used in this grinding process to control the setting properties of concrete when mixed with water.

It is known that the concrete industry has a big impact on the environment large amounts of natural resources are used for aggregate and cement production, the cement manufacturing process is energy intensive and is responsible for 58 of the global anthropogenic carbon dioxide but not least, the construction sector is an important producer of waste.

Conditions, allowing us to create new cement recipes and develop tailor made mastercem facility is ideal for testing specific cement formulations, and is a valuable resource for data 110 scale grinding plant closedcircuit, twochamber ball mill.

WhatsApp)

WhatsApp)